What is Servo Motor Progressive Die

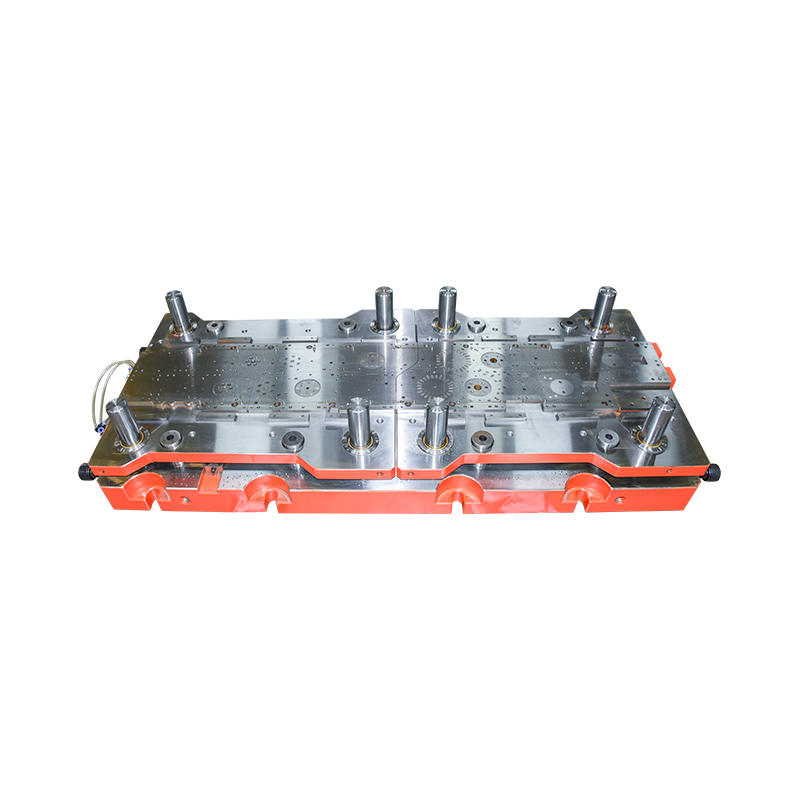

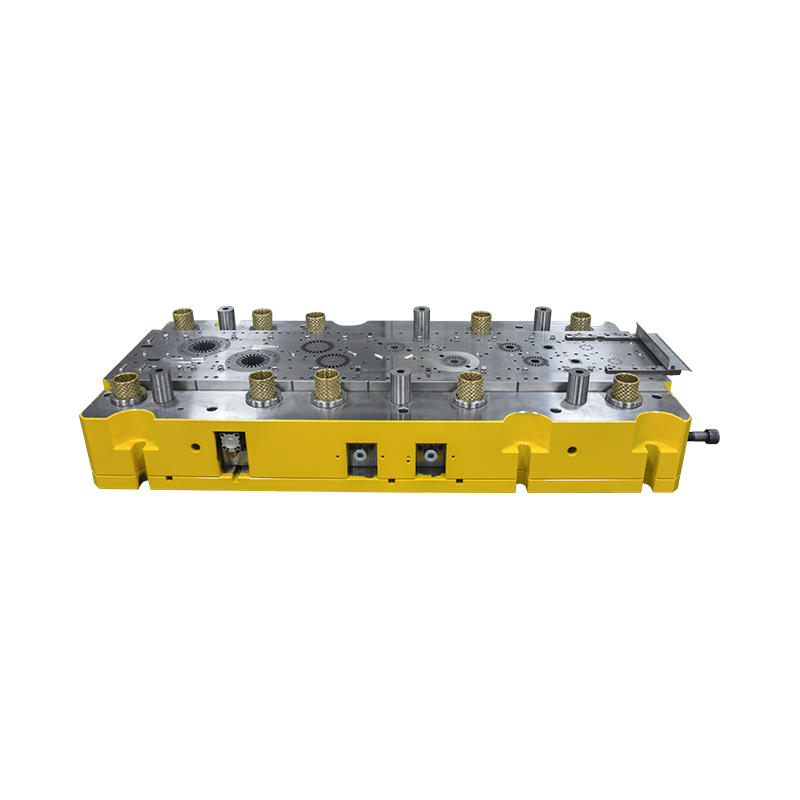

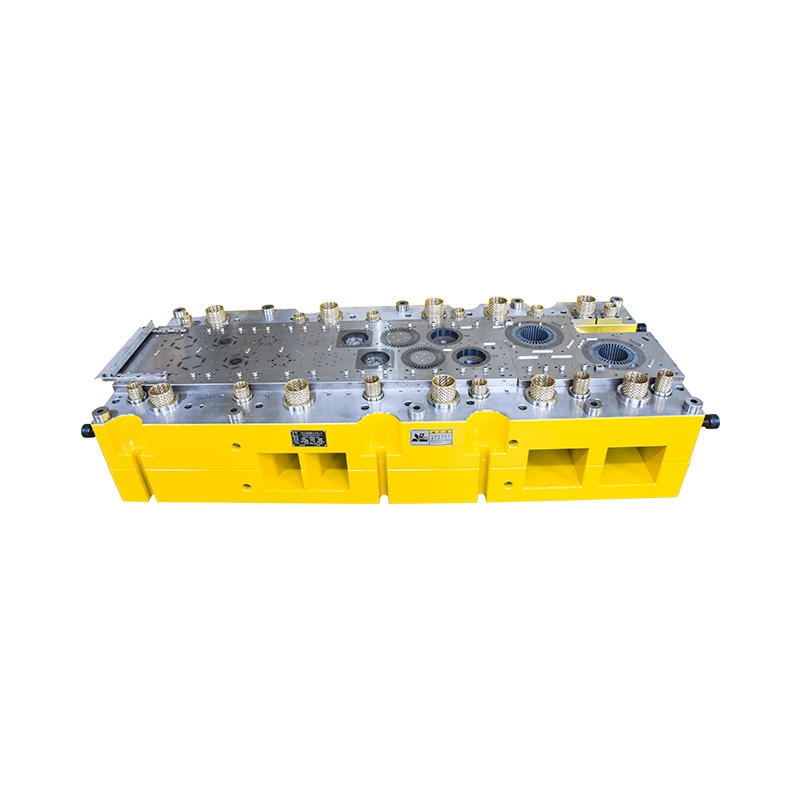

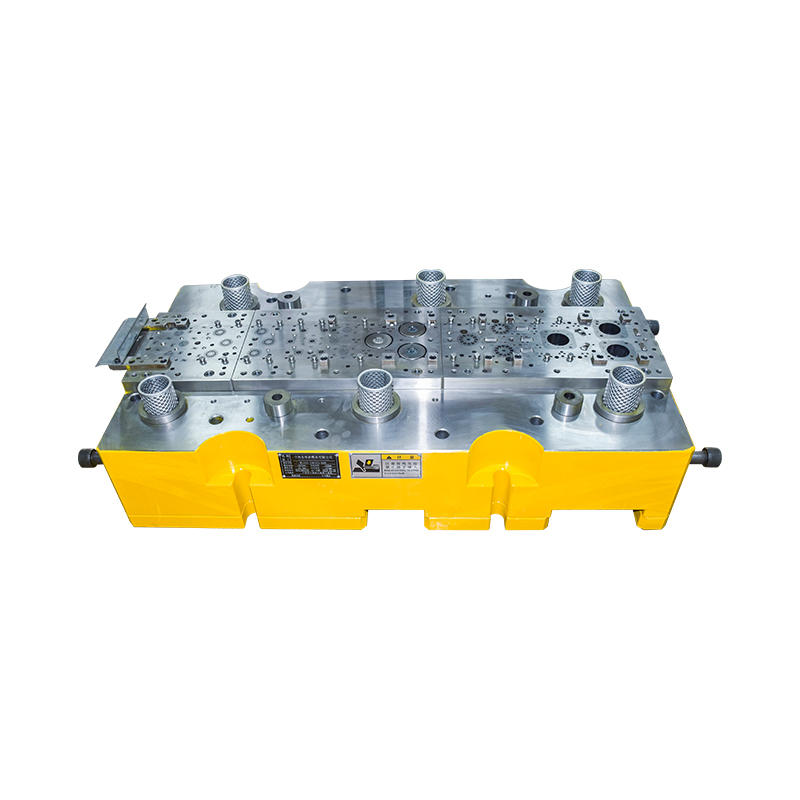

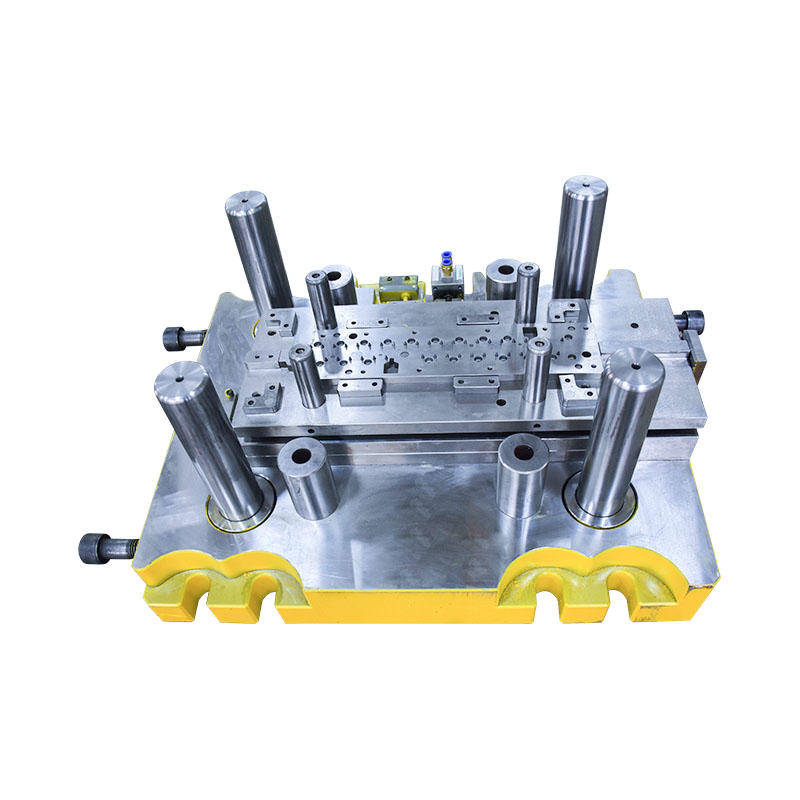

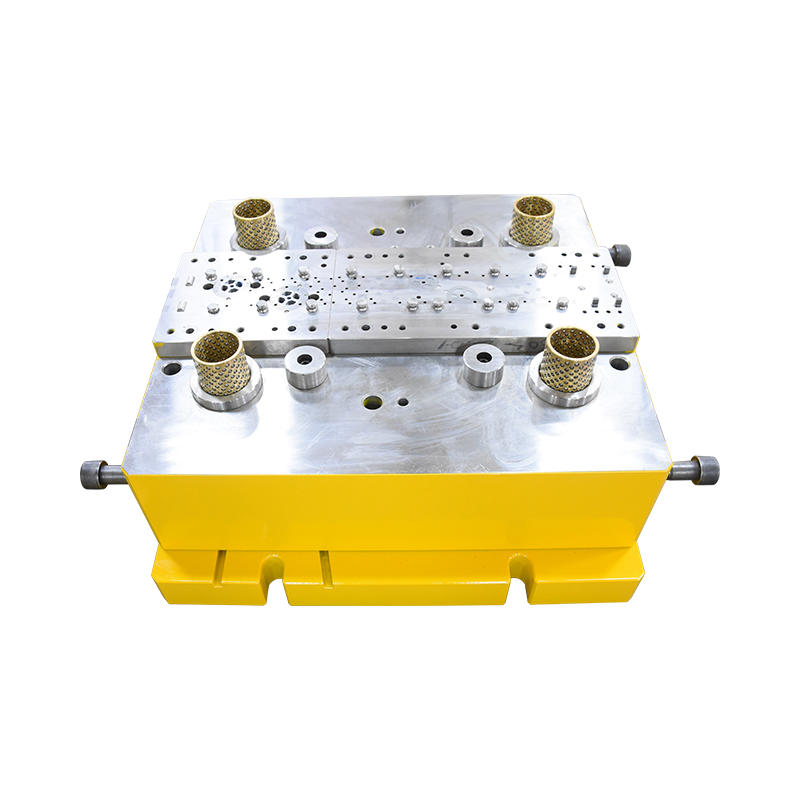

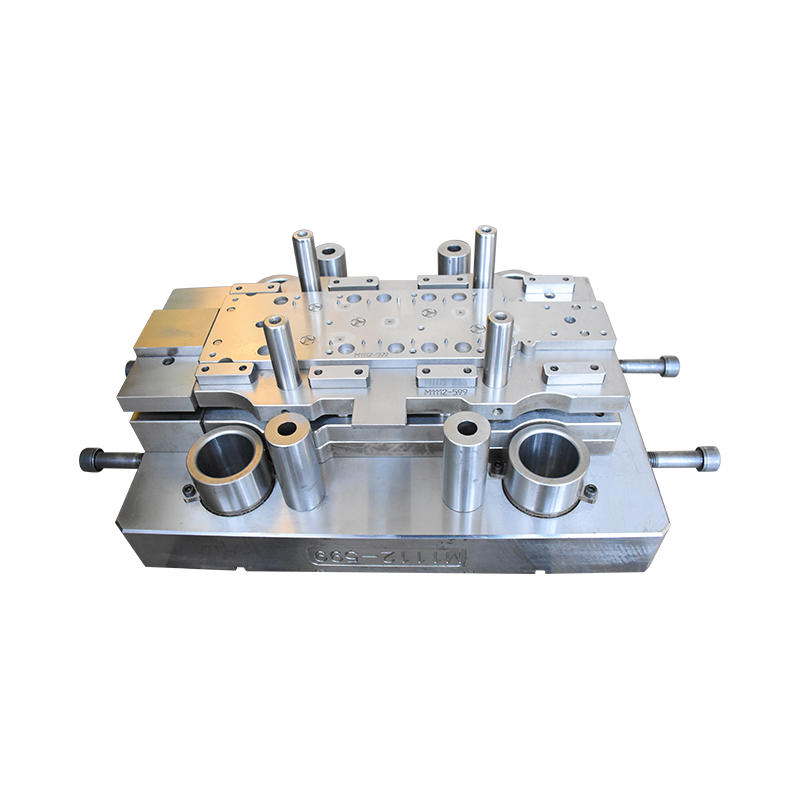

A servo motor progressive die refers to a specific type of die used in metal stamping or forming processes, where the die is driven by a servo motor system. A progressive die is a tool used in manufacturing to produce parts or components in a progressive manner. It consists of a series of stations or operations that are performed sequentially as the material passes through the die.

In a traditional progressive die, mechanical linkages or hydraulic systems are used to drive the die operations. However, in a servo motor progressive die, the die operations are driven by a servo motor system. A servo motor is an electric motor that incorporates a feedback control mechanism, allowing for precise control over the motor's position, speed, and torque.

By using a servo motor system, a servo motor progressive die offers several advantages. Firstly, it provides precise and programmable control over the die operations, allowing for flexibility in adjusting the speed, position, and force applied during the stamping process. This level of control enables manufacturers to achieve high accuracy, tight tolerances, and consistent part quality.

Additionally, servo motor progressive dies offer improved productivity and efficiency. The servo motor's quick response time enables faster operation cycles, reducing production time and increasing throughput. The programmability of the servo motor system also allows for automation and integration with other manufacturing processes, enhancing overall productivity.

Moreover, servo motor progressive dies can be more energy-efficient compared to traditional mechanical or hydraulic systems. Servo motors consume power only as needed, eliminating energy waste during idle or non-operational periods.

Overall, servo motor progressive dies are an advanced and precise tool for metal stamping operations, offering increased control, productivity, and energy efficiency in the manufacturing process.

The Advantages of Using Servo Motor Progressive Dies for Complex Parts

When it comes to producing complex parts, servo motor progressive dies offer several advantages over traditional die systems. Here are some of the key benefits:

1. Enhanced Precision: Servo motor control allows for precise and programmable movements, enabling tight tolerances and high accuracy. This level of control is crucial for complex parts that require intricate shapes, intricate features, or close dimensional specifications. The ability to adjust the speed, position, and force applied during the stamping process ensures consistent part quality and reduces the risk of errors or defects.

2. Flexibility and Versatility: Servo motor progressive dies offer greater flexibility in terms of customization and adaptability. They can accommodate a wide range of part designs and easily accommodate design changes. The programmable nature of servo motors allows for quick adjustments and modifications, making it easier to produce different variations of complex parts without the need for significant tooling changes or downtime.

3. Improved Production Efficiency: Servo motor progressive dies enable faster operation cycles, resulting in improved production efficiency. The precise control over speed and movement allows for optimized processing times, reducing overall production time and increasing throughput. This increased efficiency is particularly beneficial for complex parts that require multiple operations or intricate forming processes.

4. Lower Scrap Rates: The high precision and control offered by servo motor progressive dies contribute to lower scrap rates. With tighter tolerances and consistent part quality, the number of rejected or defective parts is minimized. This leads to cost savings by reducing material waste and lowering the need for rework or scrap reprocessing.

5. Reduced Setup Time: Servo motor progressive dies simplify the setup process compared to traditional die systems. The programmable nature of servo motors enables quick and automated adjustments, reducing the time required for tool changes or reconfiguration. This allows for faster changeovers between different part runs and increases overall production efficiency.

6. Energy Efficiency: Servo motors are known for their energy-efficient operation. They consume power only as needed, eliminating energy waste during idle or non-operational periods. Compared to traditional hydraulic or mechanical systems, servo motor progressive dies can offer energy savings, resulting in lower operational costs and a more environmentally friendly manufacturing process.

Overall, the advantages of using servo motor progressive dies for complex parts include enhanced precision, flexibility, improved production efficiency, lower scrap rates, reduced setup time, and energy efficiency. These benefits make servo motor progressive dies an excellent choice for manufacturing complex parts with demanding specifications and intricate designs.

The Impact of Servo Motor Technology on Automotive Part Production

Servo motor technology has had a significant impact on automotive part production, revolutionizing various aspects of the manufacturing process. Here are some key ways in which servo motor technology has influenced automotive part production:

1. Precision and Accuracy: Automotive parts often require tight tolerances and precise movements during manufacturing. Servo motors provide high precision and accuracy due to their ability to control position, speed, and torque with great precision. This level of control ensures consistent quality and dimensional accuracy in the production of automotive parts, resulting in improved fit, performance, and reliability of the final products.

2. Flexibility and Adaptability: Automotive manufacturers constantly face the challenge of producing a wide range of parts with varying designs and specifications. Servo motors offer excellent flexibility and adaptability in manufacturing processes. They can be easily programmed to accommodate different part variations, allowing for quick changeovers and minimizing downtime. This flexibility enables automotive manufacturers to respond swiftly to design changes, customization requests, and market demands.

3. Increased Productivity and Efficiency: Servo motor technology enables faster operation cycles, leading to increased productivity and efficiency in automotive part production. The quick response time and precise control of servo motors result in reduced processing times, shorter cycle times, and higher throughput. This efficiency improvement translates into higher production volumes, reduced lead times, and improved overall manufacturing productivity.

4. Energy Efficiency: The energy-efficient nature of servo motors is another significant advantage for automotive part production. Unlike traditional hydraulic or pneumatic systems that continuously consume energy, servo motors consume power only as required. They can be programmed to operate at optimal energy levels, resulting in reduced energy consumption and lower operational costs. This energy efficiency contributes to a more sustainable and environmentally friendly manufacturing process.

5. Advanced Automation and Integration: Servo motor technology plays a crucial role in enabling advanced automation and integration in automotive part production. The precise and programmable control offered by servo motors allows for seamless integration with robotic systems, conveyor systems, and other automation equipment. This integration improves process flow, reduces manual labor requirements, and enhances overall manufacturing efficiency.

6. Quality Improvement and Traceability: Servo motors enable the implementation of advanced monitoring and feedback systems in automotive part production. With precise control and position feedback, manufacturers can monitor the process in real-time, identify deviations or anomalies, and make necessary adjustments to maintain quality standards. Additionally, servo motor technology facilitates data collection and traceability, enabling manufacturers to track and analyze production data for quality control, process optimization, and continuous improvement.

Overall, servo motor technology has had a transformative impact on automotive part production, offering enhanced precision, flexibility, productivity, energy efficiency, and automation capabilities. It has become a vital component in modern automotive manufacturing, enabling the production of high-quality parts with improved efficiency and responsiveness to market demands.

Contact Us

Contact Us

英语

英语 中文简体

中文简体 西班牙语

西班牙语 俄语

俄语 德语

德语