The Role of Progressive Die Manufacturing in Fan Motor Development

Progressive die manufacturing plays a crucial role in the development and production of fan motors. Here are some key aspects where progressive die manufacturing contributes:

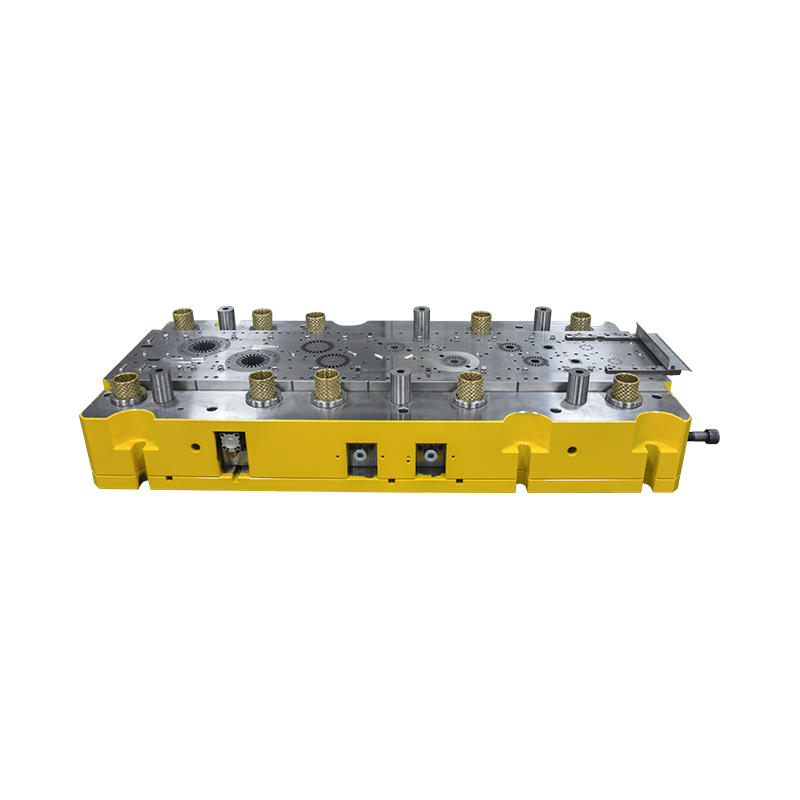

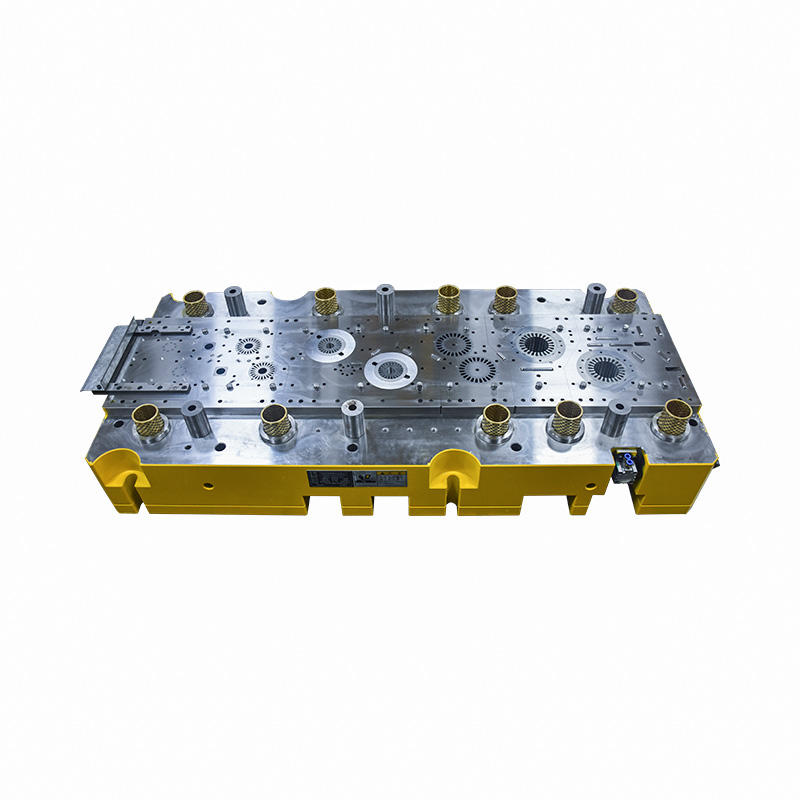

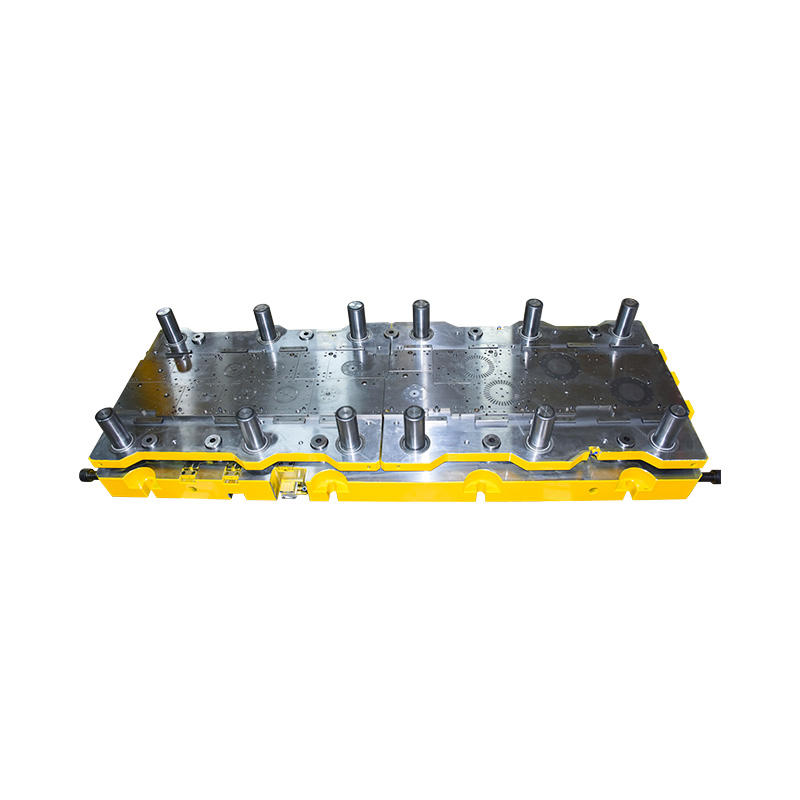

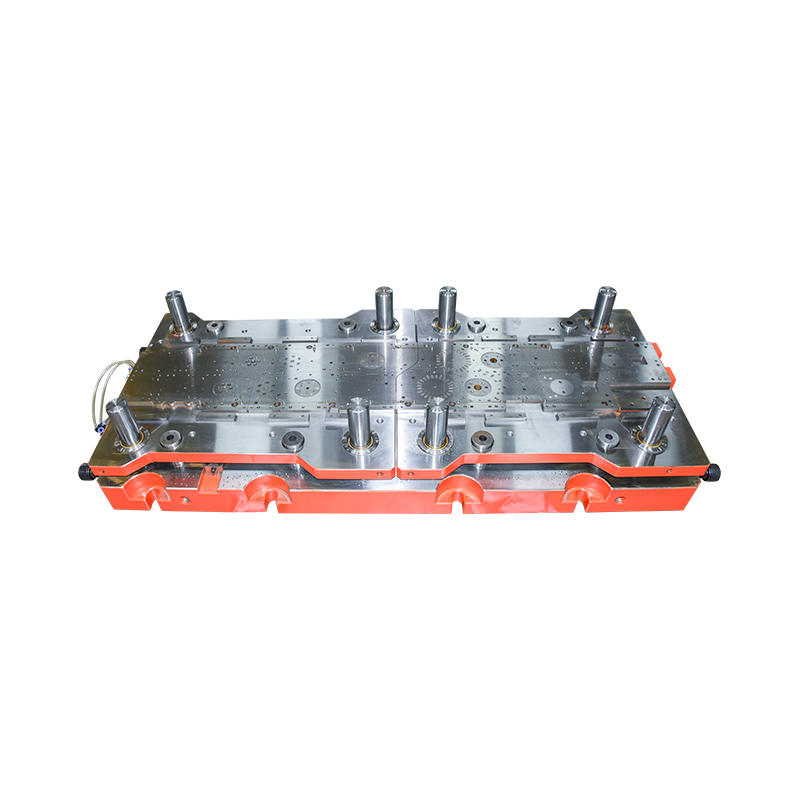

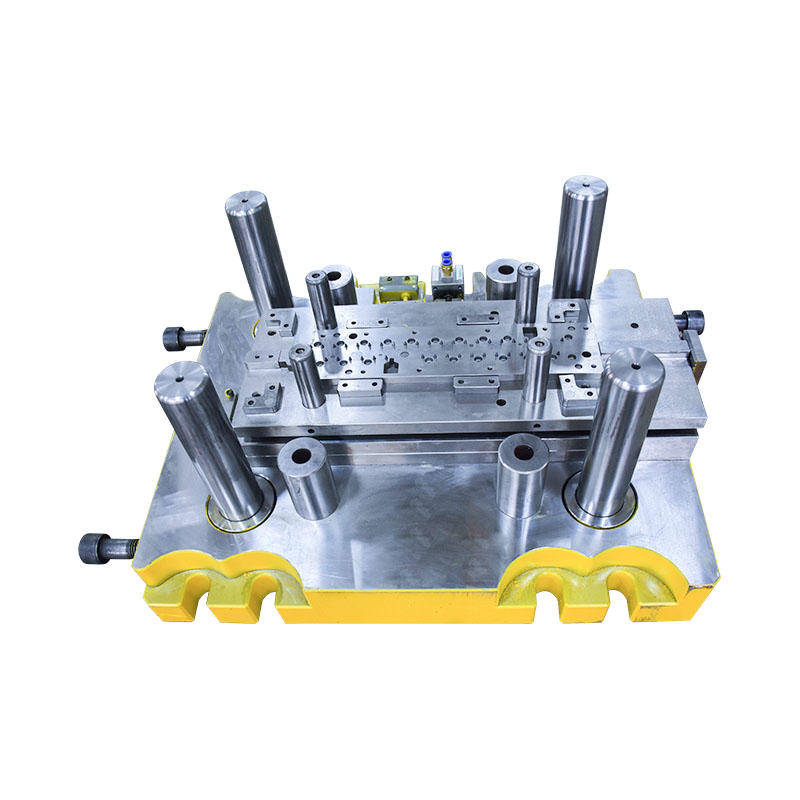

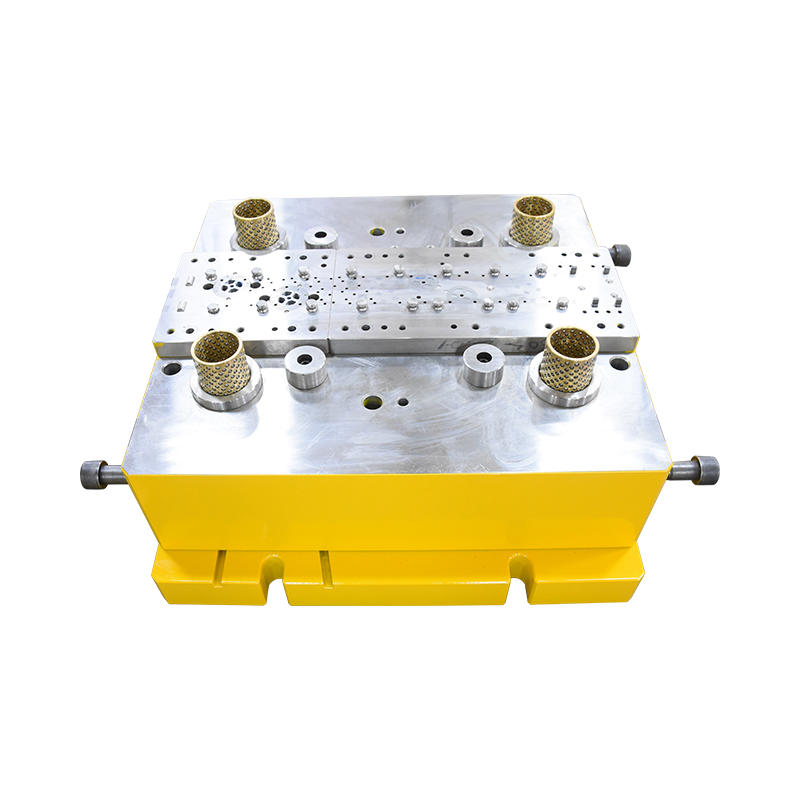

1. Stamping Motor Components: Fan motors consist of various metal components, such as stators, rotors, laminations, and housings. Progressive dies are used to efficiently stamp these components from metal sheets or strips. The dies are designed to perform multiple operations, such as cutting, bending, forming, and piercing, in a sequential manner as the material moves through the die stations. This allows for high-speed and precise production of motor components.

2. High Volume Production: Progressive die manufacturing is well-suited for high-volume production due to its ability to produce large quantities of components rapidly. The progressive die setup enables continuous processing and automation, minimizing production time and costs. Fan motor manufacturers can meet the demand for mass production with consistent quality and efficiency.

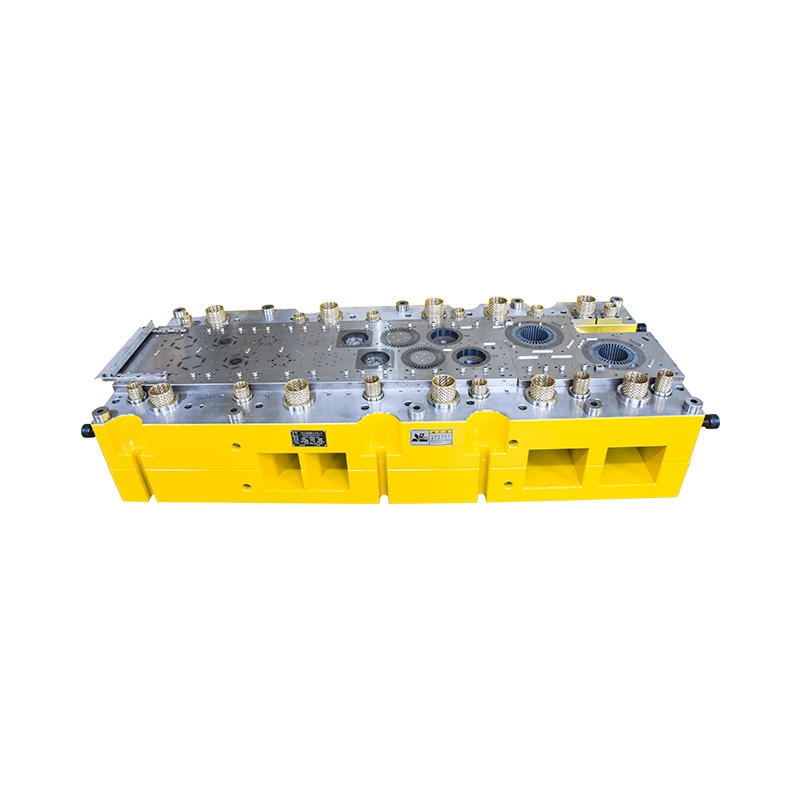

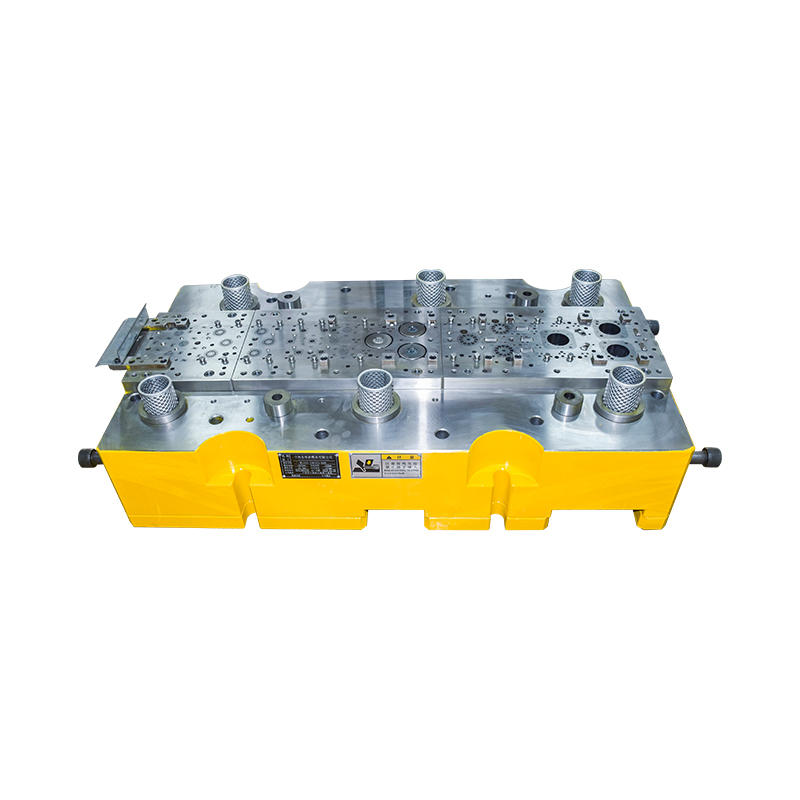

3. Complex Geometries: Fan motors often require intricate and complex geometries in their components to achieve optimal performance. Progressive dies can be designed to incorporate various shaping and forming operations, allowing for the creation of complex shapes and features. This flexibility in die design enables the production of fan motor components with precise dimensions and intricate details.

4. Cost Efficiency: Progressive die manufacturing offers cost advantages through its high-speed production capabilities, reduced material waste, and improved operational efficiency. The progressive die setup allows for simultaneous processing of multiple components, reducing production time and labor costs. Additionally, the precise control provided by progressive dies minimizes material waste, contributing to cost savings.

5. Quality and Consistency: Progressive dies provide consistent and repeatable results, ensuring uniformity in the manufactured components. The sequential operations performed by the die stations ensure precise alignment and dimensional accuracy of the stamped parts. This leads to improved quality control and reliability in fan motor production.

Overall, progressive die manufacturing plays a significant role in fan motor development by enabling efficient, high-volume production of complex components with consistent quality and cost efficiency. It helps meet the demands of the fan motor industry for reliable and high-performance products.

Enhancing Fan Motor Performance Through Progressive Die Design

Progressive die design can contribute to enhancing fan motor performance in several ways. Here are some aspects where progressive die design can make a difference:

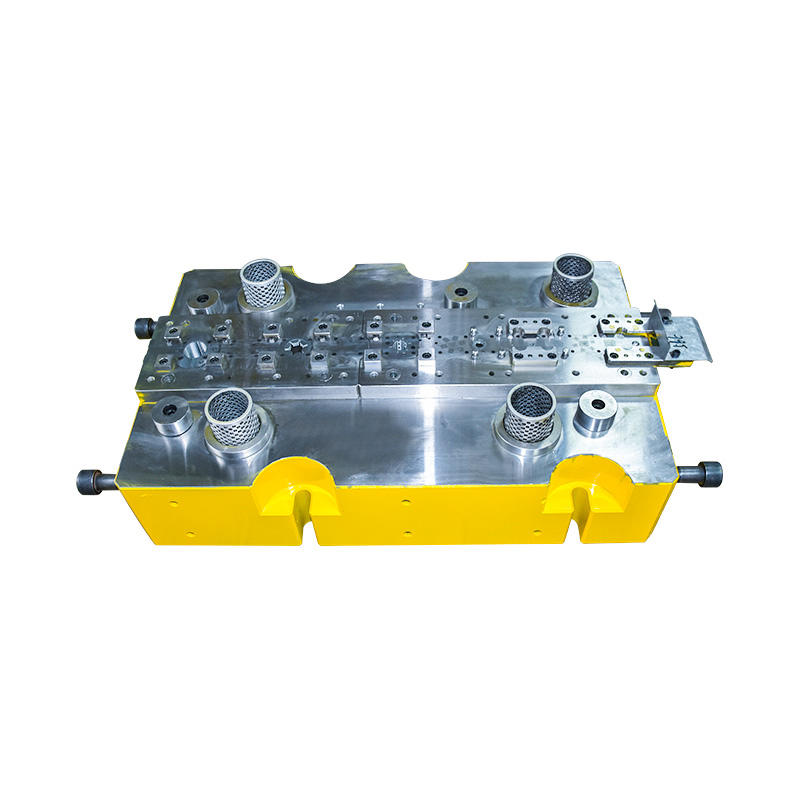

1. Optimal Material Usage: Progressive die design aims to minimize material waste during the stamping process. By optimizing the layout and configuration of the die stations, the design can help maximize material utilization. This leads to cost savings and efficient use of resources, which can be beneficial for fan motor manufacturers.

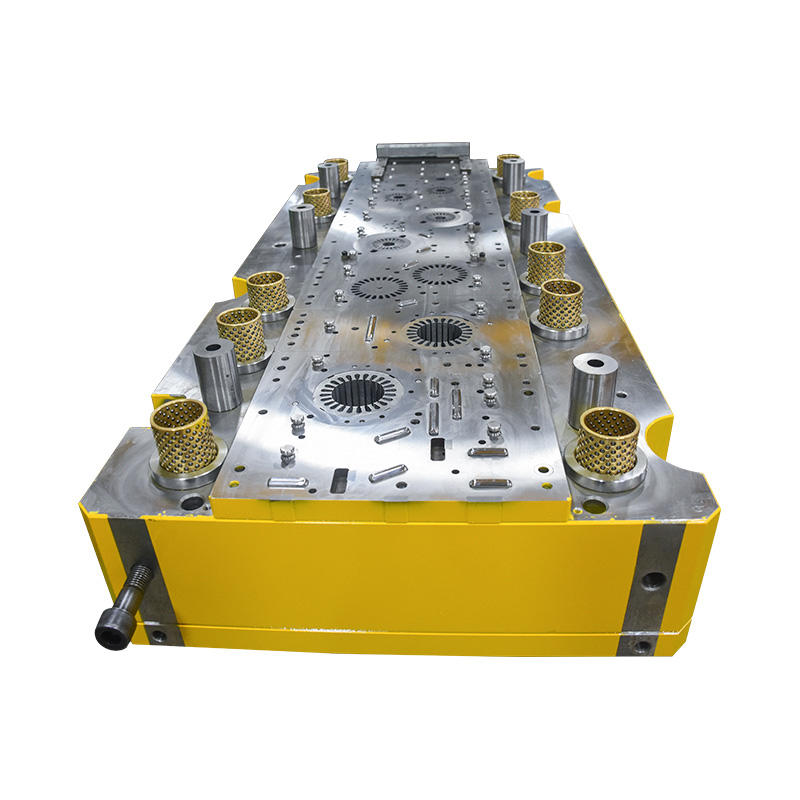

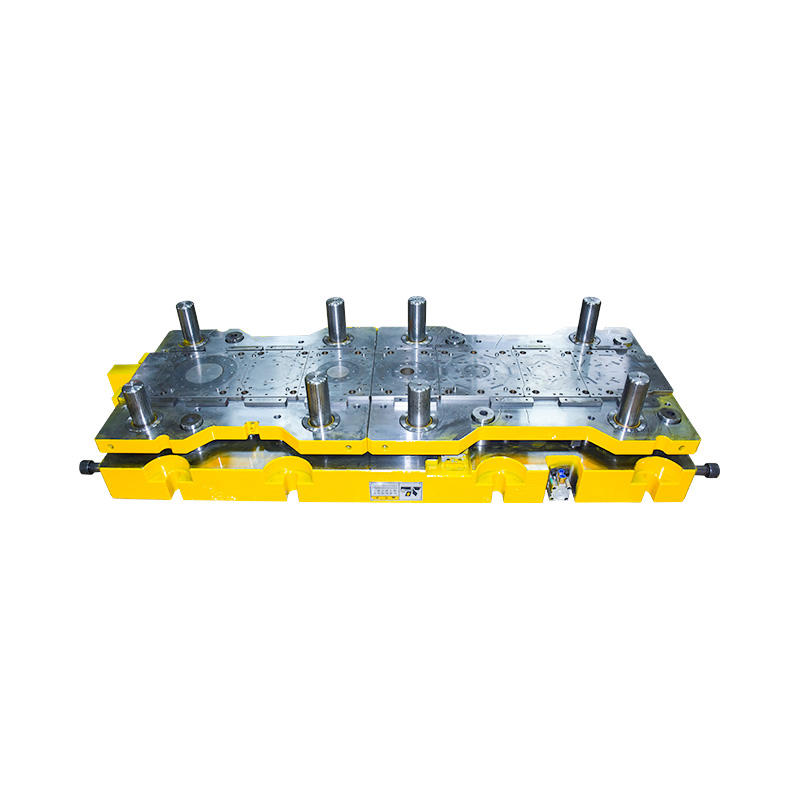

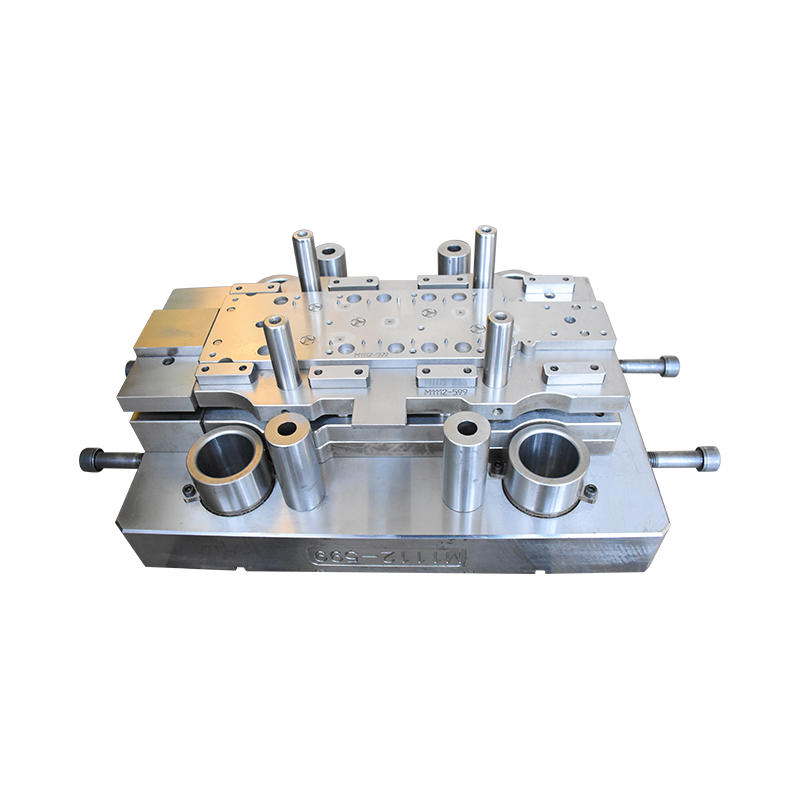

2. Precise Component Dimensions: Progressive dies can be designed with tight tolerances to ensure precise dimensions of fan motor components. Accurate and consistent component dimensions are crucial for the proper functioning of the motor. By achieving precise dimensional control during the stamping process, progressive die design contributes to the performance and reliability of the fan motor.

3. Improved Component Strength and Durability: Fan motors operate under various load conditions, and the components must withstand these forces without deformation or failure. Progressive die design can incorporate features such as strengthening ribs, embossments, or reinforcement structures in the stamped components. These design elements enhance the strength and durability of the components, ensuring their ability to withstand the operational demands of the fan motor.

4. Reduced Vibration and Noise: Vibration and noise reduction are essential considerations in fan motor design. Progressive die design can incorporate features that minimize vibration and noise generation. For example, the design can include precision cuts, shaping, or specific hole patterns to reduce the occurrence of unwanted vibrations or resonance within the motor components.

5. Enhanced Heat Dissipation: Fan motors often generate heat during operation, and effective heat dissipation is crucial for their performance and longevity. Progressive die design can incorporate features such as optimized fin patterns or ventilation holes in motor components. These features facilitate improved heat dissipation, allowing the fan motor to operate at optimal temperatures.

6. Streamlined Assembly: Progressive die design can also simplify the assembly process of fan motors. By incorporating features such as alignment marks, interlocking tabs, or snap-fit connections, the design can facilitate quick and accurate assembly of the stamped components. This contributes to efficient production and reduces assembly errors, resulting in improved overall motor performance.

Overall, progressive die design plays a vital role in enhancing fan motor performance by optimizing material utilization, achieving precise component dimensions, improving component strength and durability, reducing vibration and noise, enhancing heat dissipation, and streamlining assembly processes. These design considerations contribute to the overall efficiency, reliability, and performance of fan motors.

Contact Us

Contact Us

英语

英语 中文简体

中文简体 西班牙语

西班牙语 俄语

俄语 德语

德语