What is Refrigerator motor progressive die

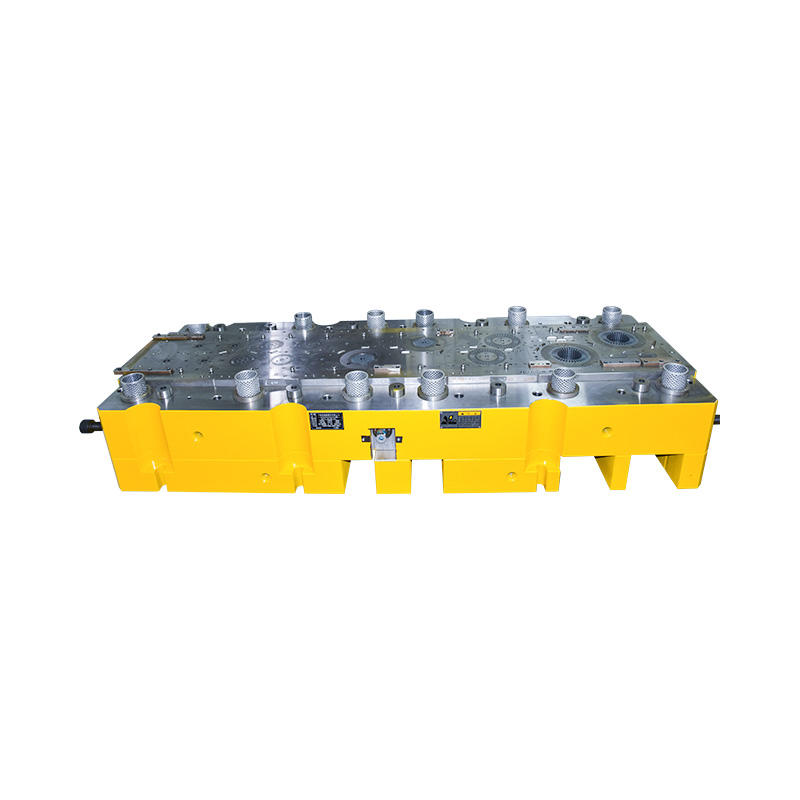

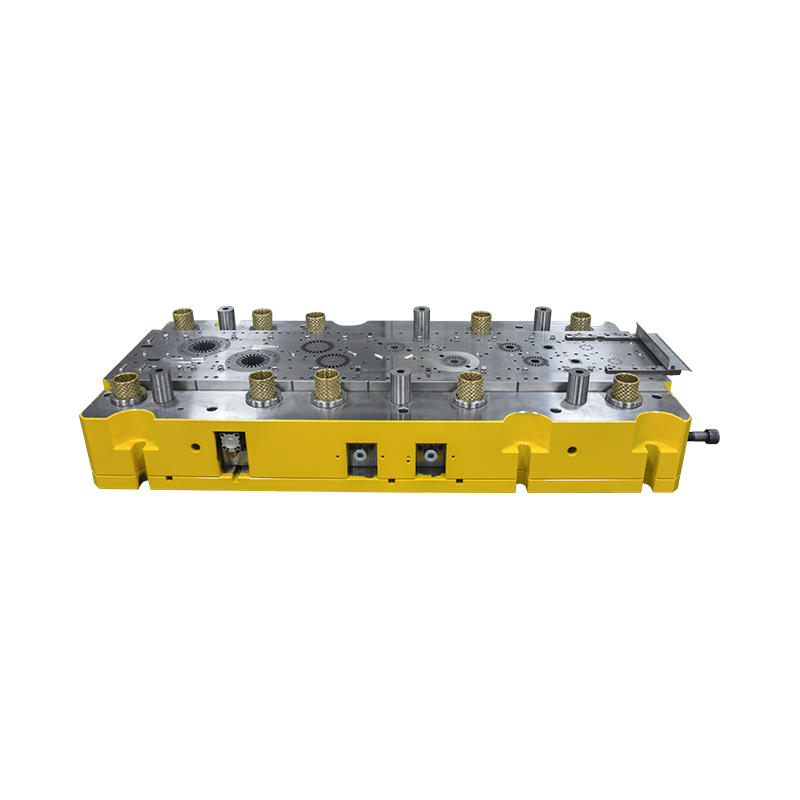

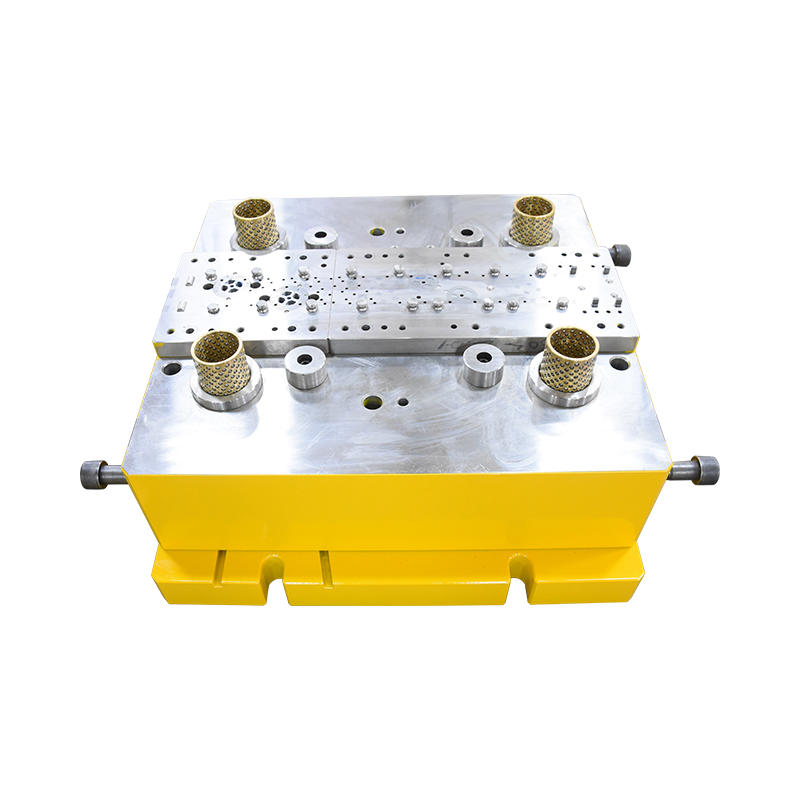

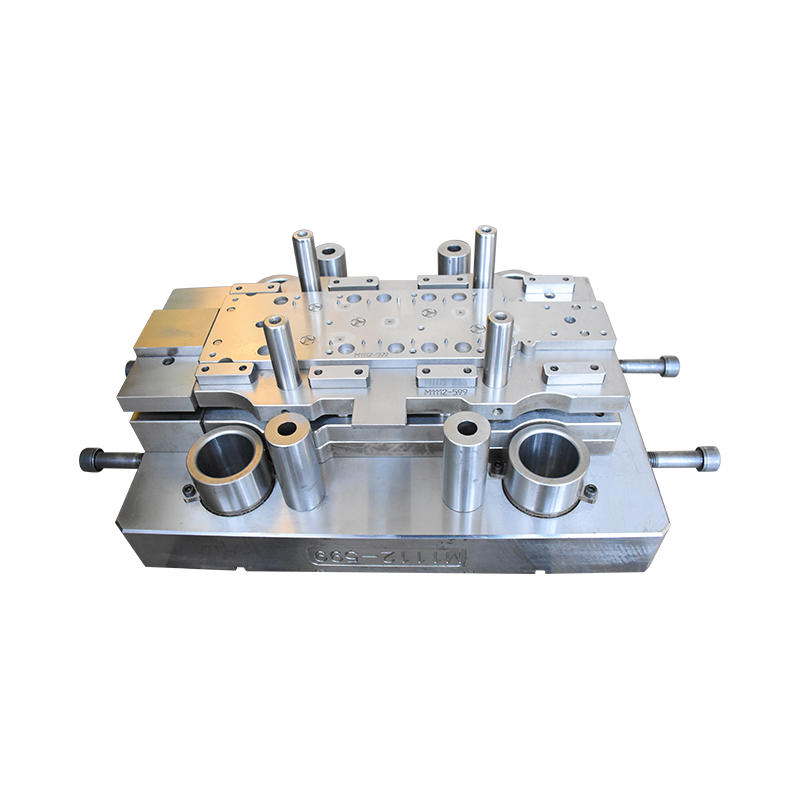

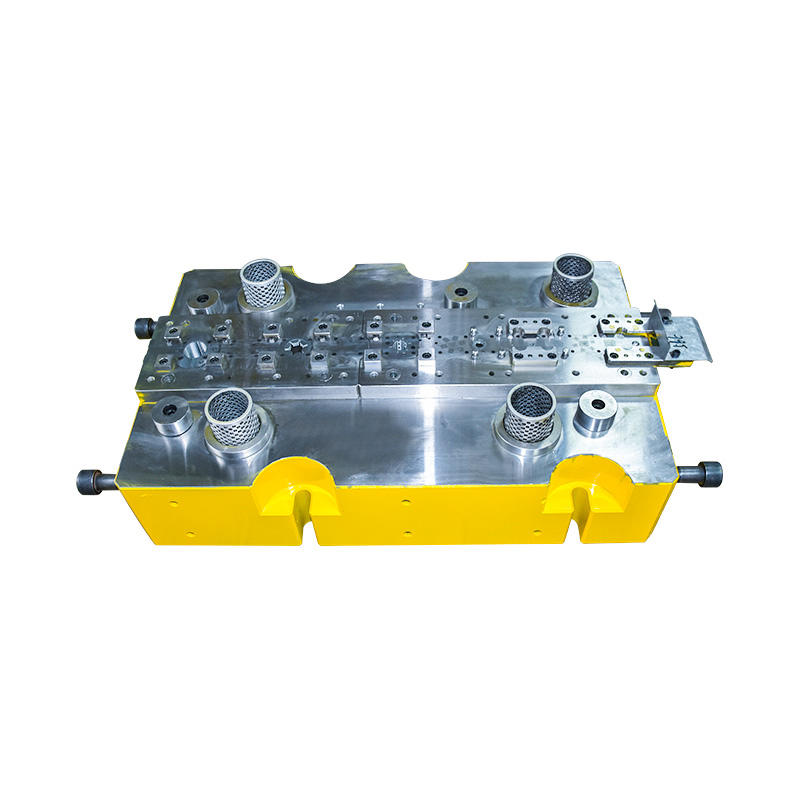

A refrigerator motor progressive die is a specialized tool used in the manufacturing process of refrigerator motors. A progressive die is a type of die that enables the simultaneous cutting, shaping, and forming of metal sheets or strips in a progressive manner.

In the context of refrigerator motors, the progressive die is used to fabricate the motor's core laminations. The core laminations are thin metal sheets or strips that are stacked together to form the core of the motor. These laminations are designed to reduce energy losses and improve the efficiency of the motor.

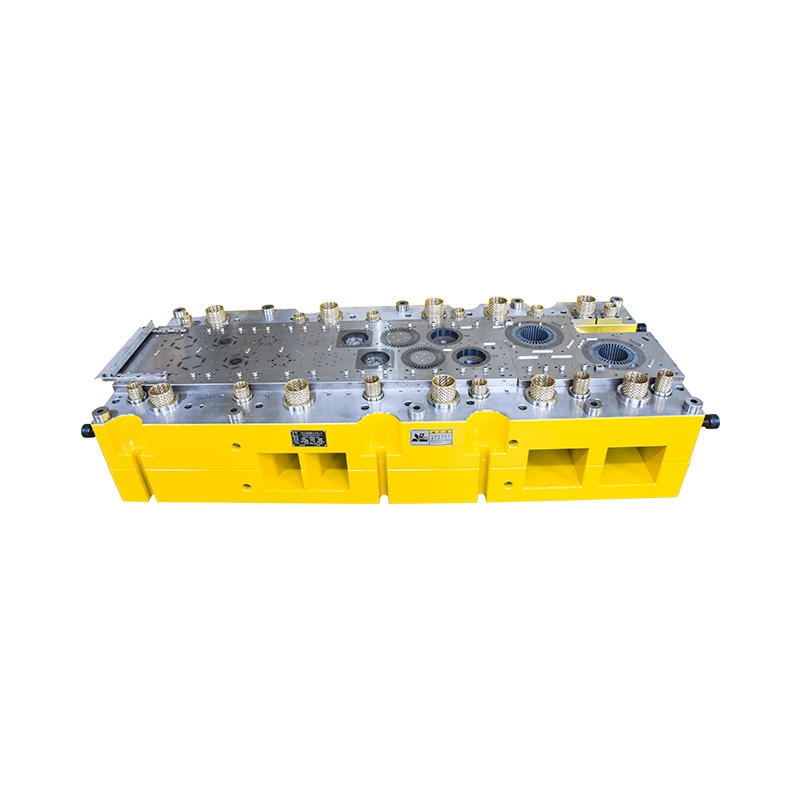

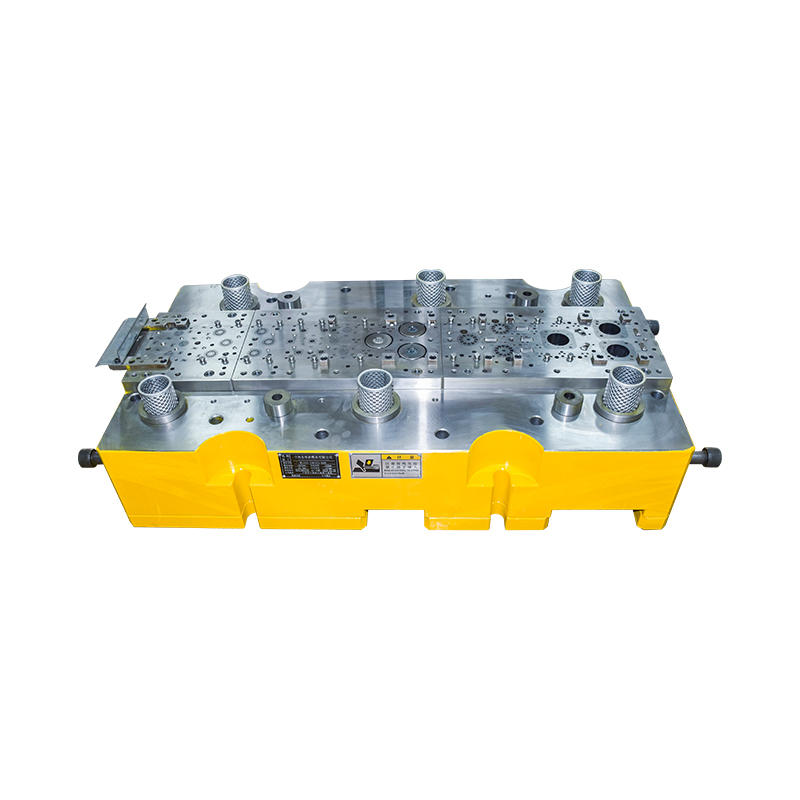

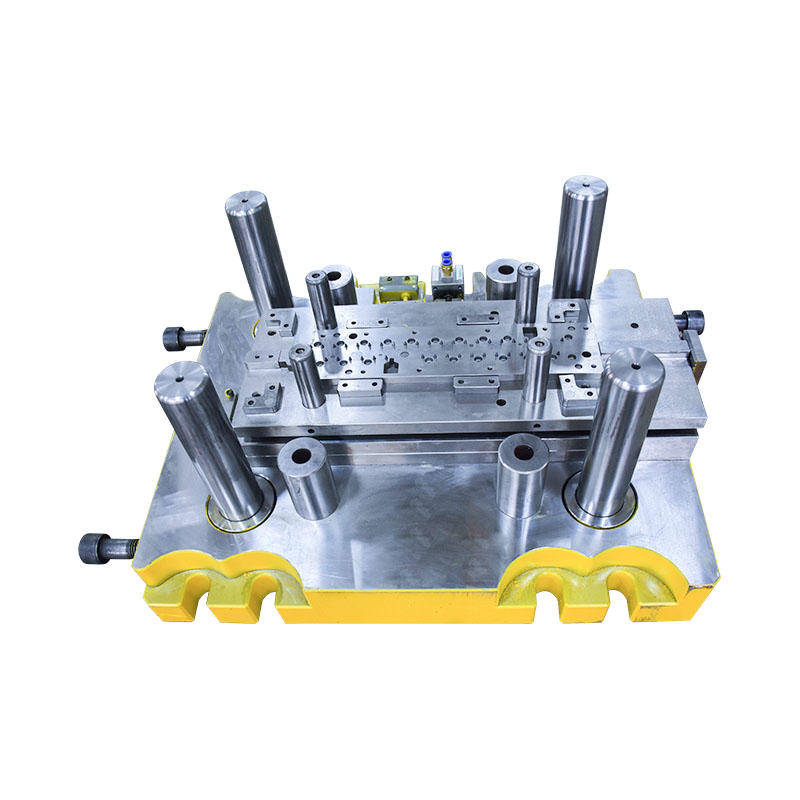

The progressive die consists of a series of stations or stages through which the metal strip passes. Each station performs a specific operation, such as cutting, bending, or punching, to shape the metal strip into the desired form. The strip is fed through the die, and as it progresses from one station to the next, it undergoes additional operations until the final shape of the lamination is achieved.

By utilizing a progressive die, manufacturers can efficiently produce a large volume of core laminations with high precision and accuracy. The progressive die allows for automation and streamlines the production process, resulting in cost-effective and consistent manufacturing of refrigerator motor core laminations.

The Role of Progressive Dies in Refrigerator Motor Manufacturing

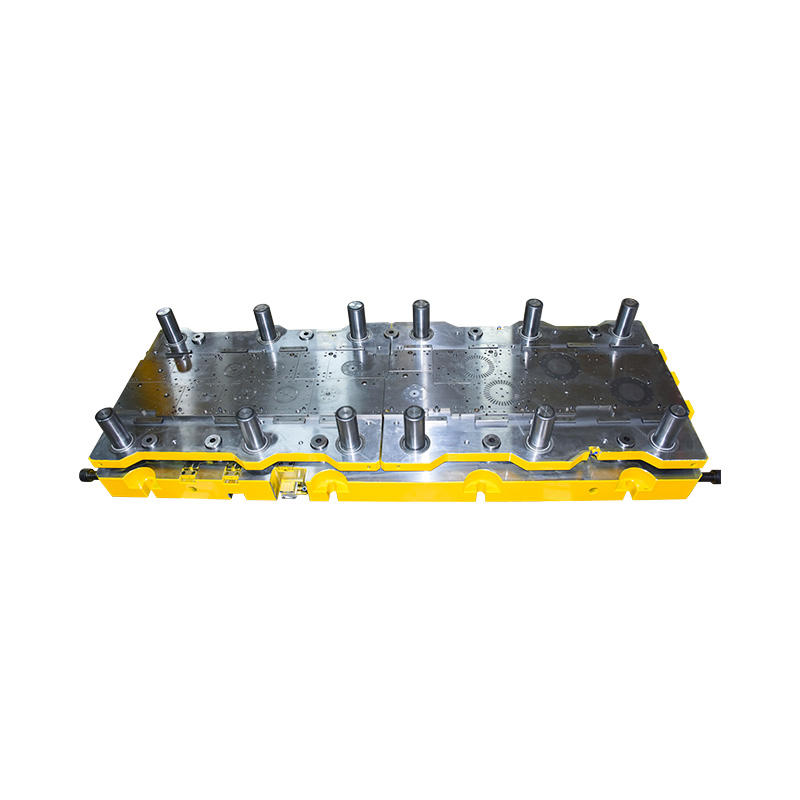

The role of progressive dies in refrigerator motor manufacturing is crucial for the efficient and cost-effective production of high-quality motors. Progressive dies offer several benefits and play a significant role in shaping and forming the core laminations of refrigerator motors. Here are some key aspects of their role:

1. Increased Productivity: Progressive dies enable continuous and automated manufacturing processes, minimizing downtime and maximizing productivity. The strip material progresses through multiple stations, undergoing various operations simultaneously, which significantly speeds up production.

2. Precision and Accuracy: Progressive dies ensure precise and accurate shaping of metal strips into the desired forms for motor core laminations. The dies are designed to provide consistent and repeatable results, maintaining tight tolerances and dimensional accuracy.

3. Material Optimization: By utilizing progressive dies, manufacturers can optimize material usage. The dies are designed to minimize waste and maximize material utilization, reducing costs and promoting sustainability.

4. Complex Shaping Capabilities: Progressive dies can perform multiple operations in a sequential manner, allowing for the creation of intricate and complex shapes required for refrigerator motor core laminations. This capability ensures that the laminations are precisely formed and meet the specific design requirements.

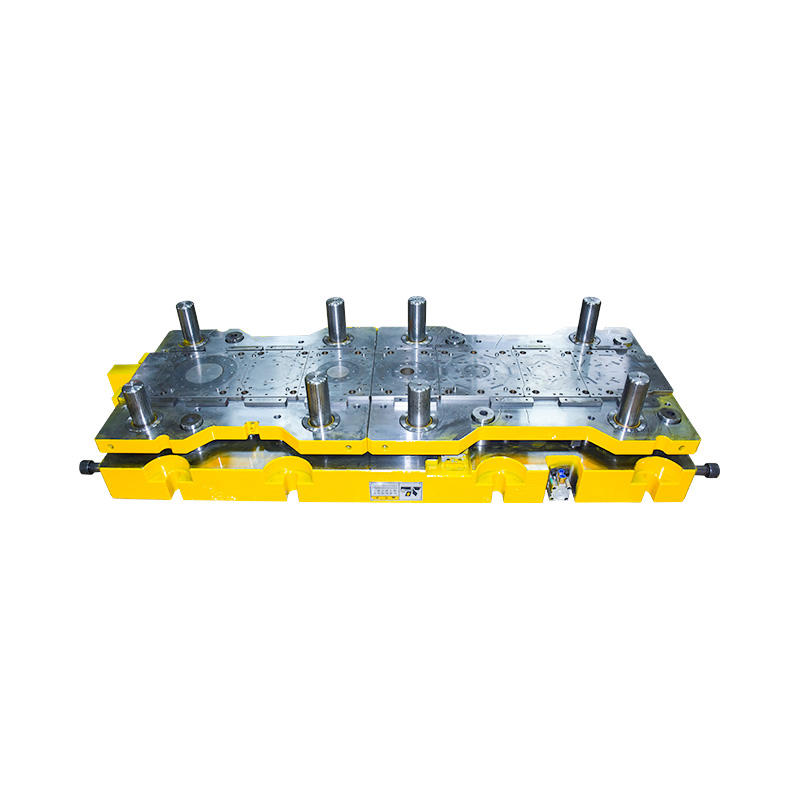

5. Cost Efficiency: Progressive dies help reduce manufacturing costs by streamlining the production process, minimizing manual labor, and optimizing material usage. The automation provided by progressive dies also reduces the likelihood of errors and rework, resulting in cost savings.

6. Consistency and Quality Control: Progressive dies offer a high level of consistency in the manufacturing process, ensuring that each lamination produced meets the desired quality standards. This consistency is essential for the overall performance and efficiency of refrigerator motors.

7. Scalability and Flexibility: Progressive dies are adaptable to different motor designs and can be modified or adjusted easily to accommodate changes in production requirements. This scalability and flexibility allow manufacturers to respond to market demands efficiently.

In summary, progressive dies play a vital role in refrigerator motor manufacturing by enhancing productivity, ensuring precision, optimizing material usage, reducing costs, maintaining quality control, and providing scalability and flexibility. Their utilization contributes to the production of efficient and reliable refrigerator motors in a cost-effective manner.

Maximizing Productivity: The Benefits of Using Progressive Dies for Refrigerator Motor Production

Using progressive dies for refrigerator motor production offers numerous benefits that contribute to maximizing productivity. These benefits are instrumental in streamlining the manufacturing process and enhancing overall efficiency. Here are some key advantages of using progressive dies:

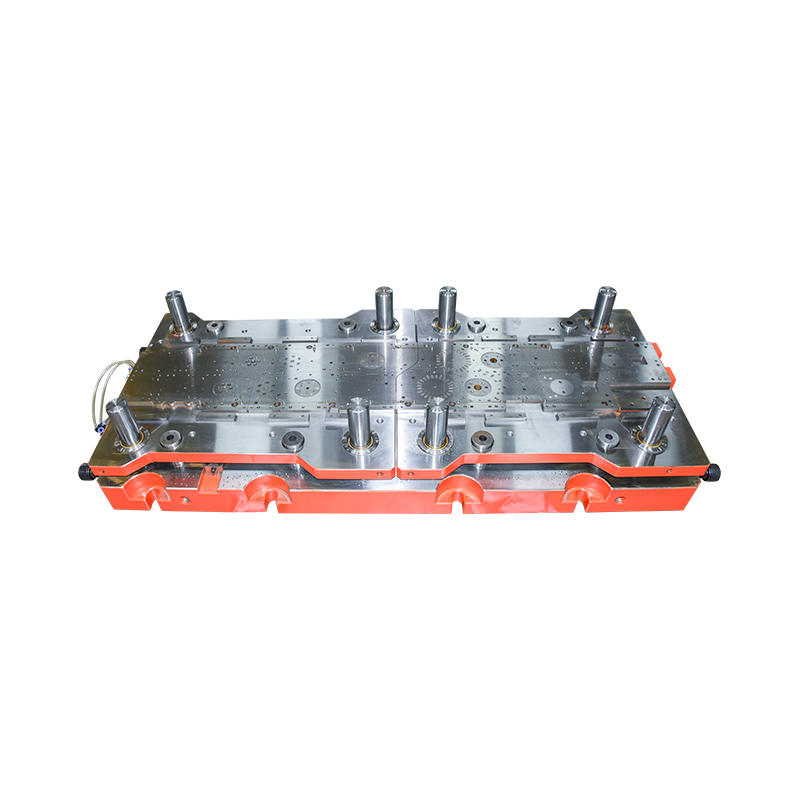

1. Simultaneous Operations: Progressive dies enable multiple operations to be performed simultaneously. As the metal strip passes through the die, it undergoes a series of sequential operations such as cutting, bending, and punching in different stations. This simultaneous processing eliminates the need for manual handling and reduces production time, thus increasing productivity.

2. Continuous Manufacturing: Progressive dies facilitate continuous manufacturing by automating the feeding and movement of the metal strip through the die. This eliminates the need for manual intervention between operations, resulting in a smooth and uninterrupted production flow.

3. Faster Cycle Times: The automation and simultaneous operations offered by progressive dies significantly reduce cycle times. As each station performs a specific operation on the metal strip, the overall production time is minimized, allowing for faster output and increased productivity.

4. High Precision and Accuracy: Progressive dies ensure precise and accurate shaping of the metal strip into the desired forms for refrigerator motor components. The dies are designed with tight tolerances and provide consistent results, ensuring that each part meets the required specifications. This precision eliminates the need for additional manual adjustments or rework, saving time and improving productivity.

5. Material Optimization: Progressive dies optimize material usage by minimizing waste and maximizing material utilization. The dies are designed to precisely cut and shape the metal strip, reducing scrap and minimizing material costs. This material optimization contributes to overall cost savings and increased productivity.

6. Flexibility for Design Changes: Progressive dies offer flexibility in accommodating design changes. If there are modifications or improvements in the motor design, the dies can be easily adjusted or modified to meet the new requirements. This flexibility enables manufacturers to adapt quickly to design changes without significant disruptions to the production process, ensuring uninterrupted productivity.

7. Consistency and Quality Control: Progressive dies provide consistent and repeatable results, ensuring uniformity in the manufactured parts. The precise operations performed by the dies maintain consistent dimensions, shapes, and quality, resulting in reliable and high-quality refrigerator motor components.

By utilizing progressive dies, manufacturers can maximize productivity through simultaneous operations, continuous manufacturing, faster cycle times, high precision, material optimization, flexibility for design changes, and consistency in quality control. These benefits contribute to efficient production processes, reduced costs, and increased output, ultimately maximizing overall productivity in refrigerator motor manufacturing.

Contact Us

Contact Us

英语

英语 中文简体

中文简体 西班牙语

西班牙语 俄语

俄语 德语

德语