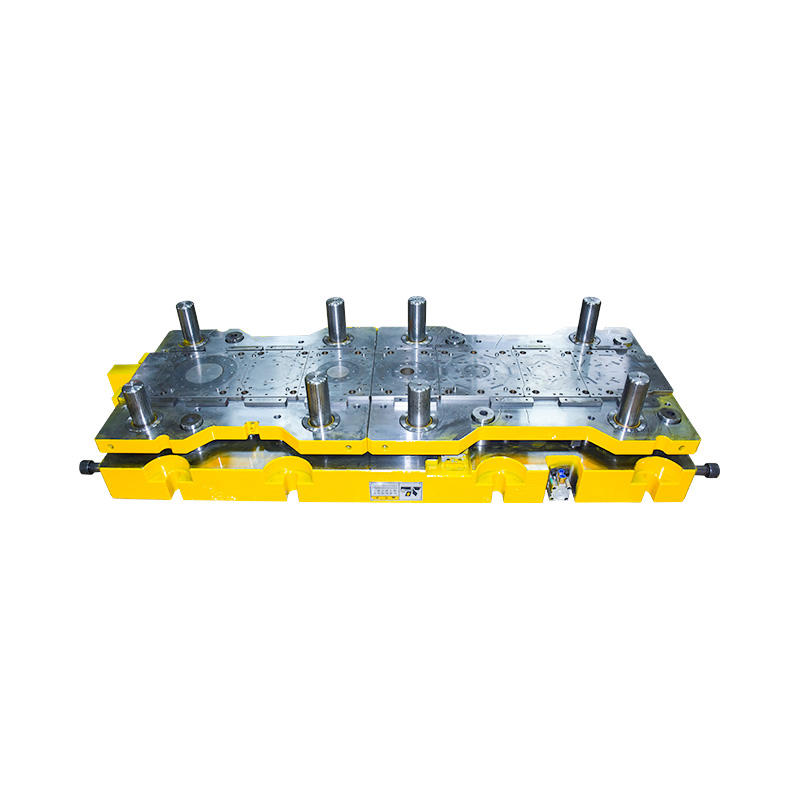

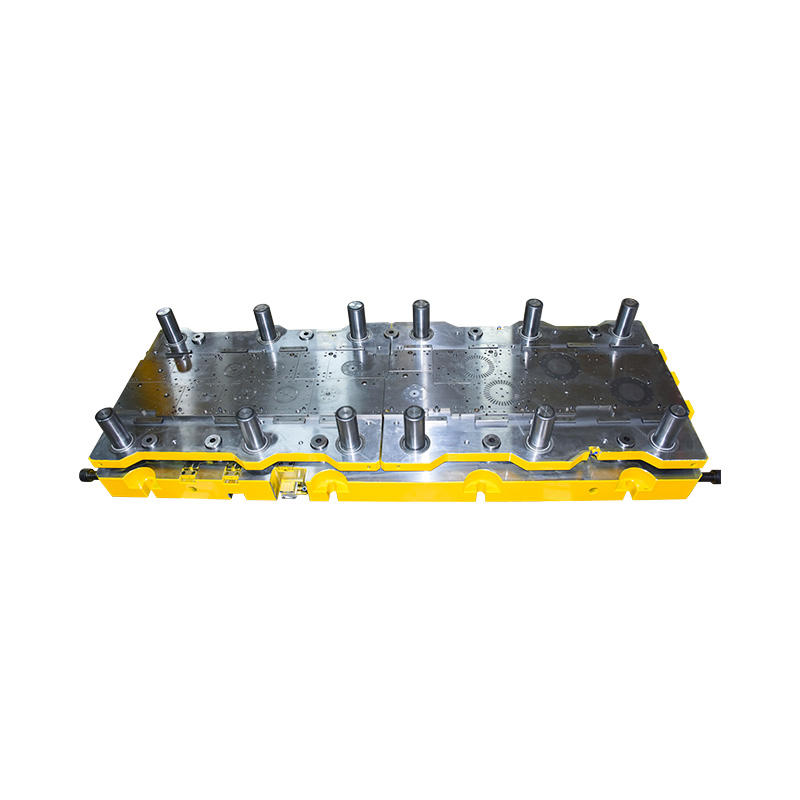

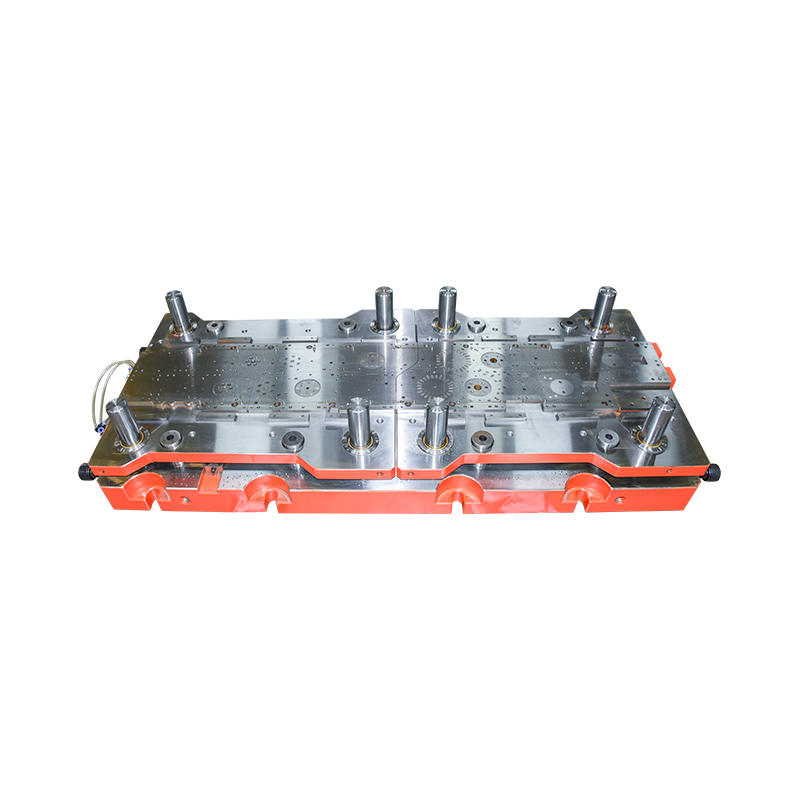

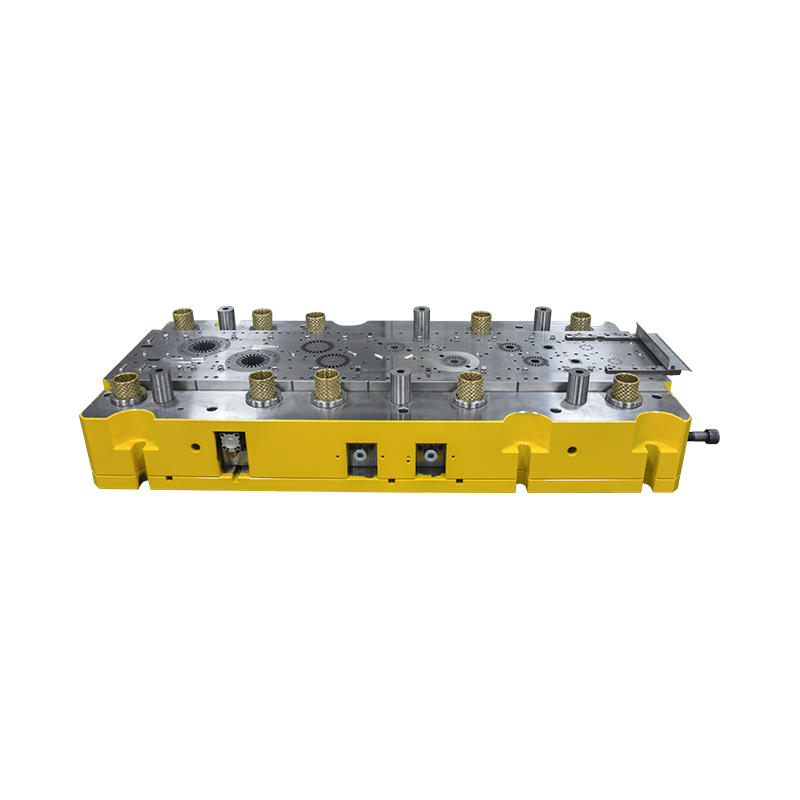

Can the motor progressive die be quickly switched to produce different parts?

The design of motor progressive die is mainly aimed at high efficiency, continuous stamping, and mass production, with a certain degree of flexibility. However, there are still some technical and practical limitations to achieve rapid switching and production of different parts. The mold structure is often tailored for a specific type of part, and the number of workstations, process arrangement, stamping sequence, positioning method, etc. inside the mold are closely related to the specific structure of the part. Therefore, a set of molds can usually only correspond to one or a type of part with similar shape and size.

In actual production, if it is necessary to change the variety of parts produced, it usually means replacing the entire mold or partially disassembling and debugging the mold structure. This process involves multiple steps such as mold handling, alignment, installation, and stamping parameter adjustment, with a long cycle and is not suitable for small batch diversified production with frequent variety changes. Especially when there are significant differences in parts or multiple process changes are involved, the complexity of mold switching operations and debugging time will further increase, which not only affects the production rhythm but may also introduce quality fluctuations or accuracy errors.

With the development of intelligent manufacturing and modular design, some high-end motor progressive die systems have begun to have stronger fast switching capabilities. For example, by adopting modular positioning structures, standardized mold seats, and CNC positioning systems, the efficiency of mold replacement can be improved to a certain extent, reducing mold switching from traditional hours to tens of minutes or even shorter. But these solutions usually require higher initial investment and supporting automation equipment, and in industrial applications, high-end customized production lines are still the main focus.

Motor progressive dies are not suitable for frequent and rapid switching of parts with different structures in production. They are more suitable for stable, batch, and highly repetitive parts manufacturing tasks. If the enterprise is facing a demand for multiple varieties, small batches, or highly variable orders, it is more suitable to choose more flexible manufacturing solutions, such as CNC stamping, composite molds, or multi station turret punching machines, to respond more efficiently to product changes. Although the motor progressive die has certain adjustment capabilities, it is not its main advantage in quickly switching between different parts.

English

English 中文简体

中文简体 Español

Español русский

русский Deutsch

Deutsch