Can the motor progressive die reserve expansion space to adapt to future production needs?

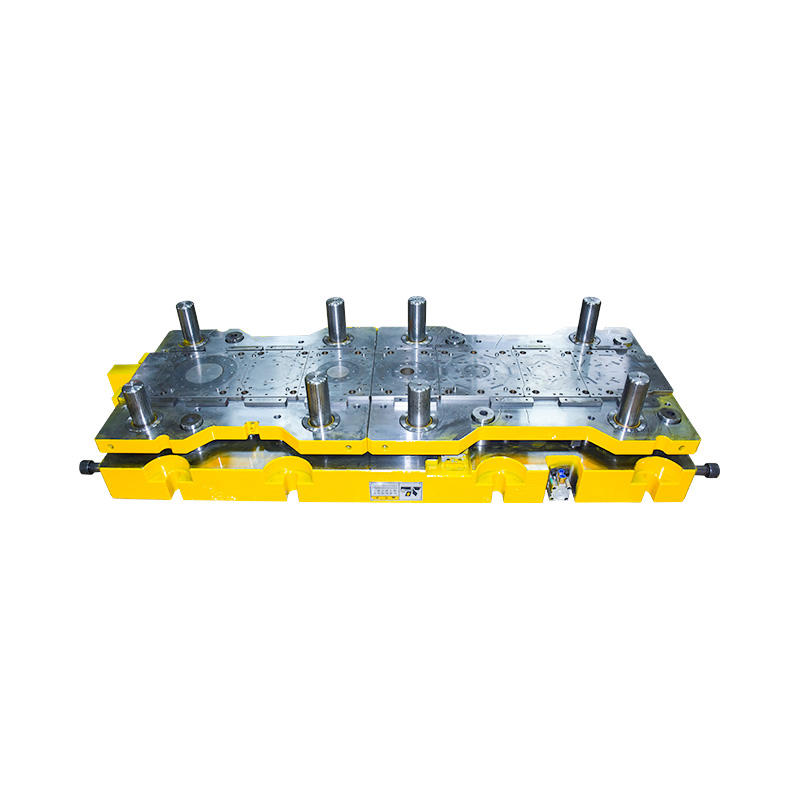

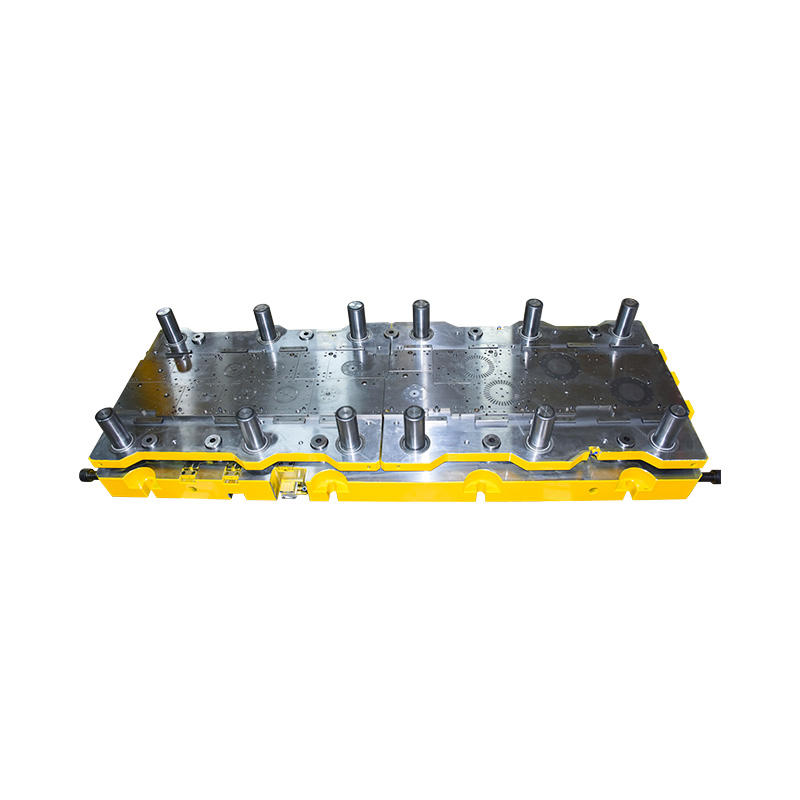

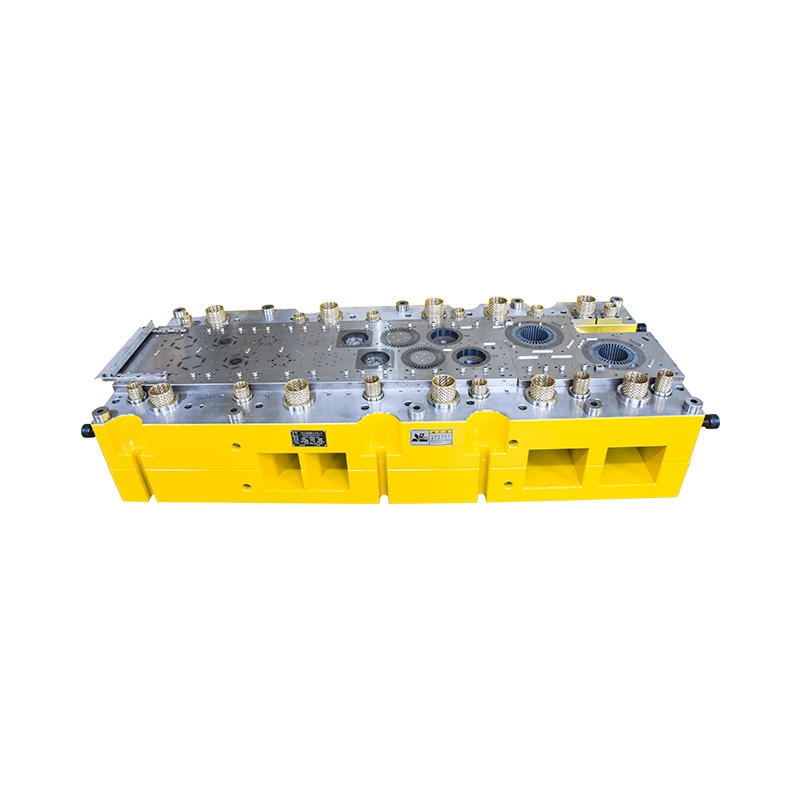

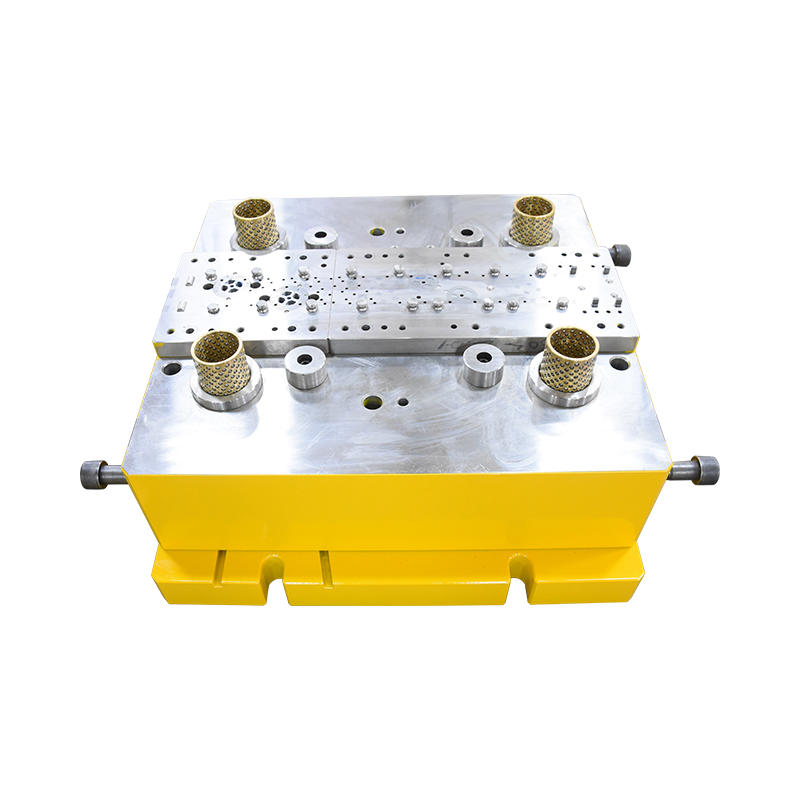

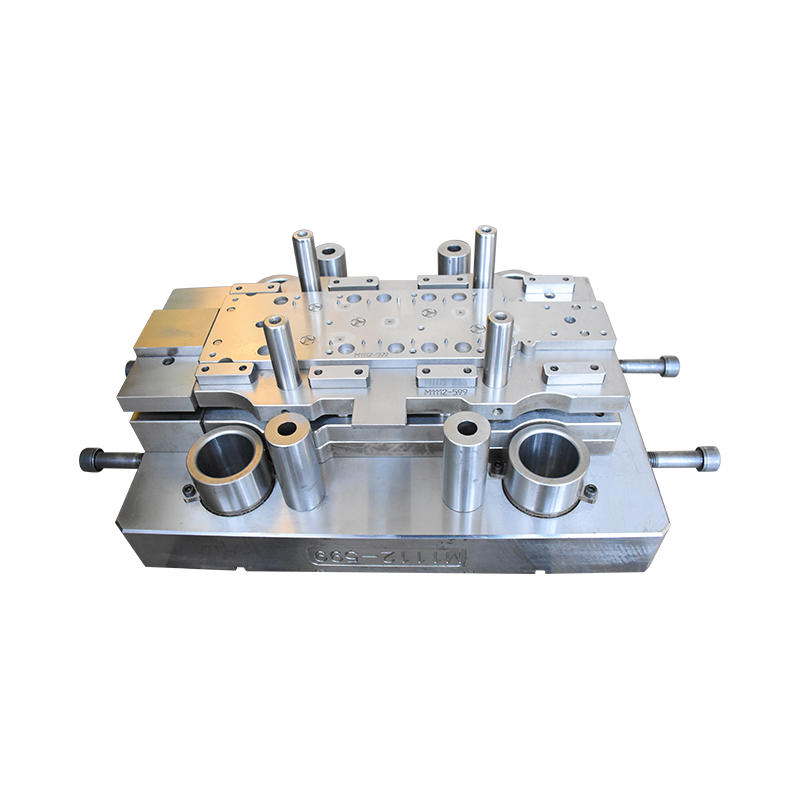

During the design of motor progressive dies, a certain amount of expansion space can be reserved to adapt to new production needs in the future, but this reservation usually requires sufficient planning and technical evaluation in the initial design stage. Motor progressive die is a highly integrated and precision matched continuous stamping die, in which each workstation, stamping action, and material guiding path are precisely designed to ensure production efficiency and product quality. On the premise of not affecting the current product performance, the expansion space in the mold structure must be arranged reasonably, otherwise it may lead to problems such as insufficient mold space, decreased strength, or inconvenient operation.

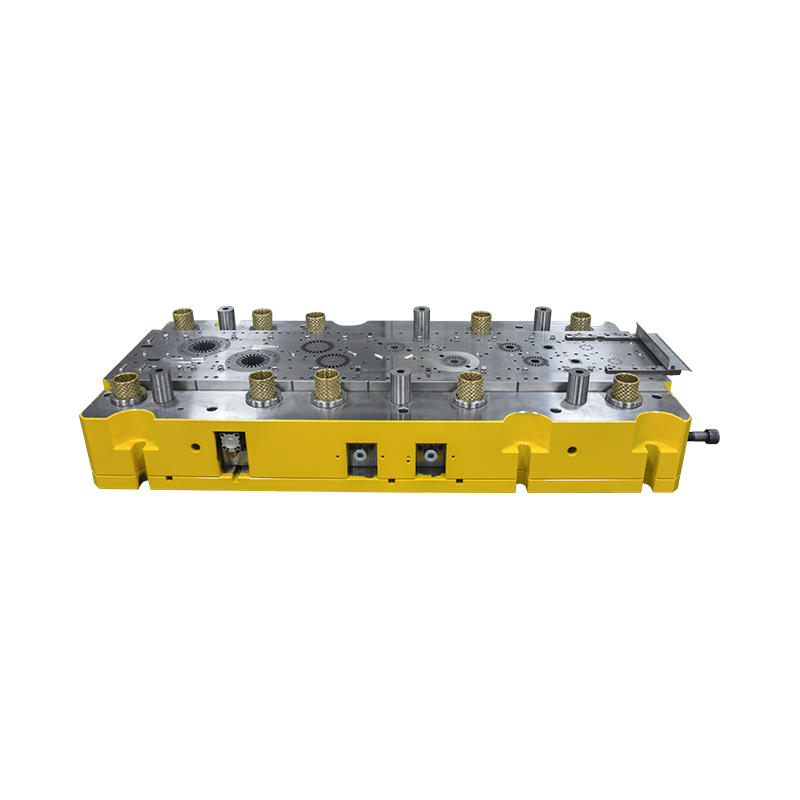

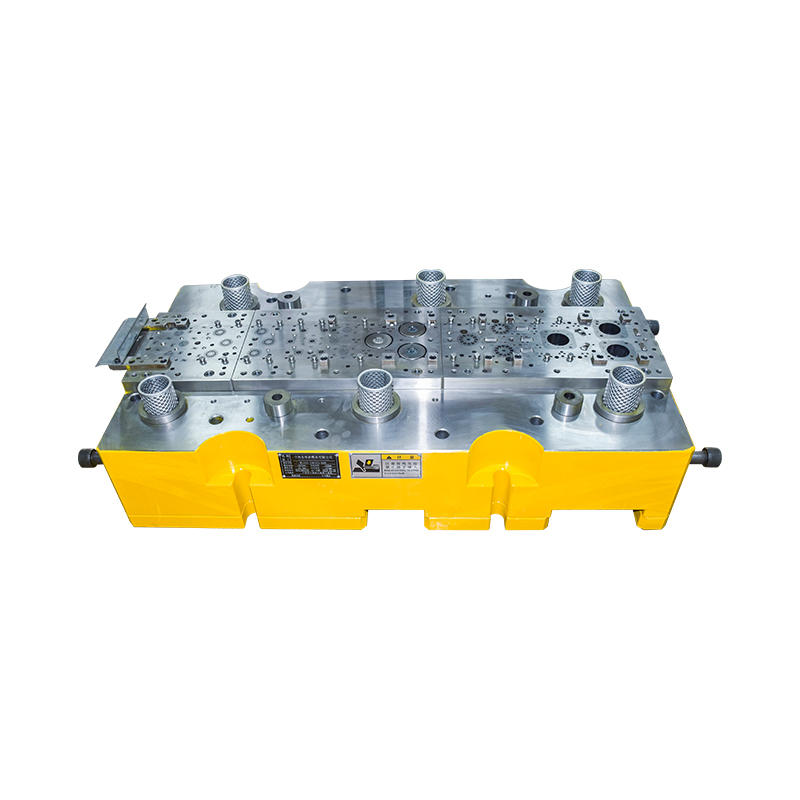

To meet potential product updates or process changes in the future, mold designers can adopt a modular concept when designing motor progressive dies. For example, some stamping stations can be designed as replaceable modules, or installation holes and guide structures can be reserved on the mold surface, so that it is not necessary to completely replace the entire mold when adding or adjusting stations. At the same time, the direction of the material strip, the guiding structure, and the unloading method can also be designed to adapt to wider or longer materials, thereby improving the compatibility of the mold.

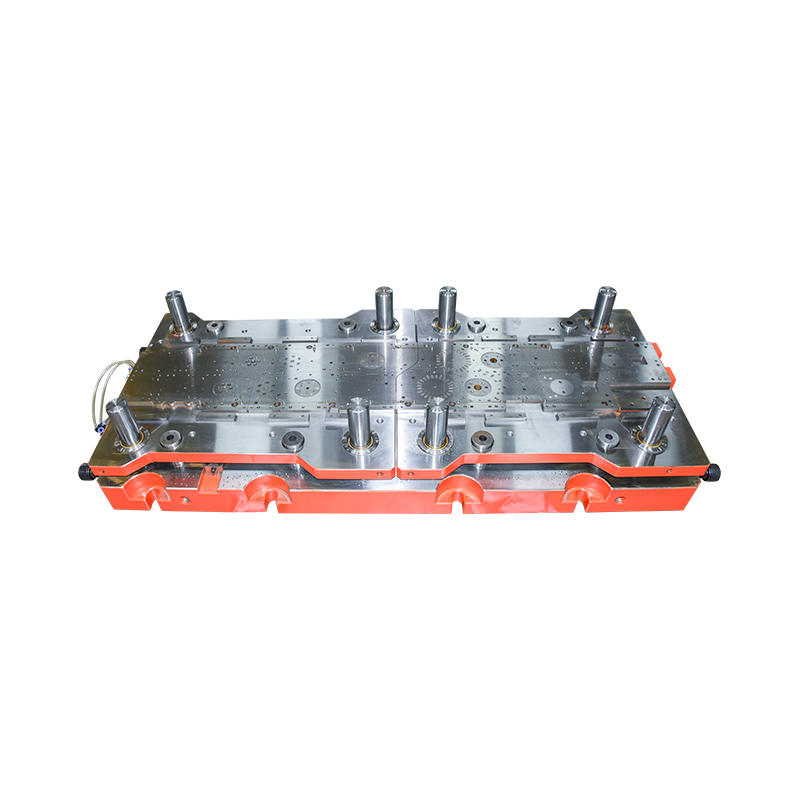

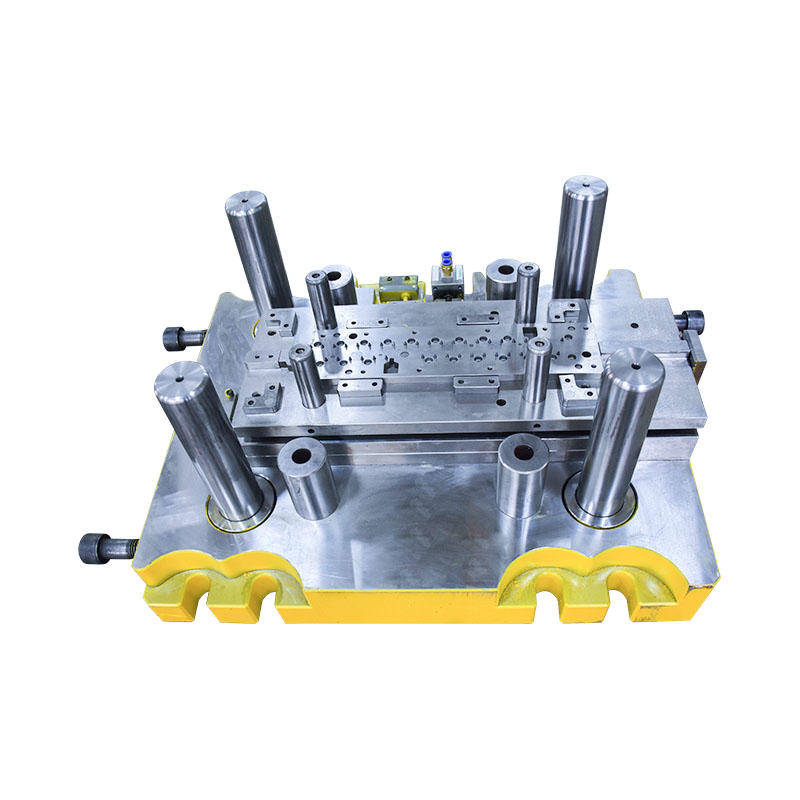

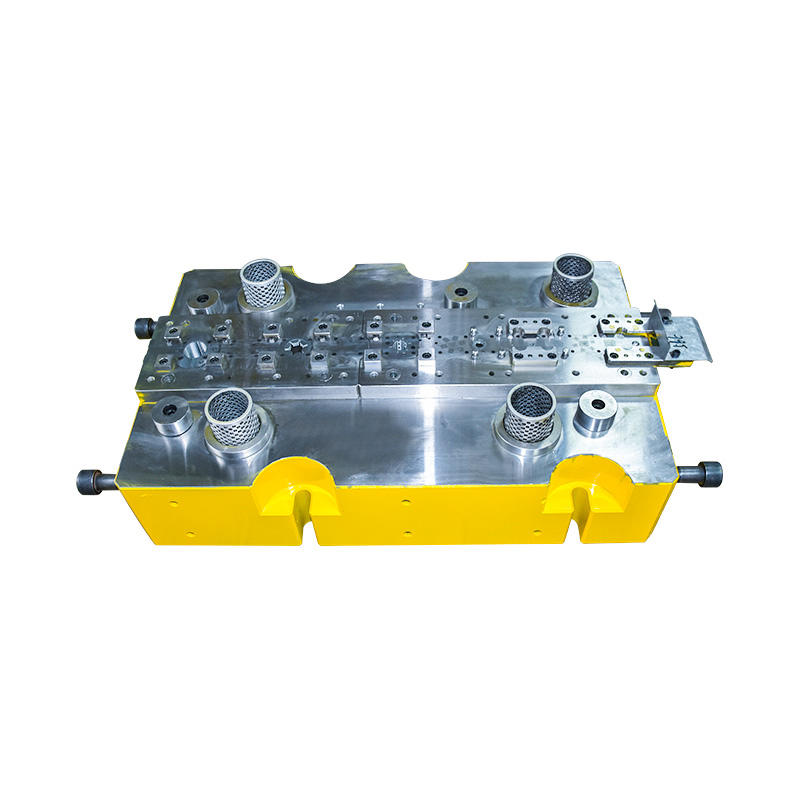

In terms of mold frame structure, universal mold frames or adjustable mold frame forms can also be selected, so that when new processes or parts need to be added or replaced, there is sufficient physical space and assembly interfaces to expand new modules or upgrade existing structures. In terms of electrical and control systems, sensor interfaces, data channels, or intelligent detection devices can also be reserved to provide basic support for future intelligent production.

This design of reserving expansion space also involves a certain cost and technical trade-off. On the one hand, reserving space and redundant structures may increase the initial manufacturing cost of the mold, occupy more materials, and processing time; On the other hand, excessive reservation may lead to a decrease in the overall rigidity of the mold and a deterioration in its operational stability. In practical applications, whether to reserve expansion space needs to be comprehensively considered based on the enterprise's product lifecycle, production flexibility requirements, and future development plans.

English

English 中文简体

中文简体 Español

Español русский

русский Deutsch

Deutsch