Can the mold structure of the motor progressive die be adjusted and designed according to the complexity of the product?

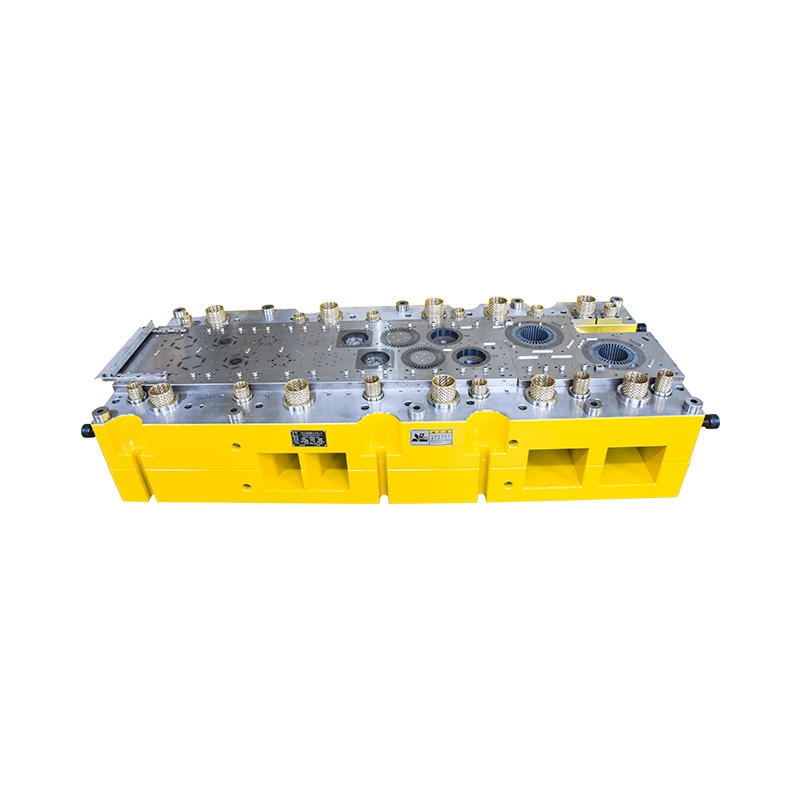

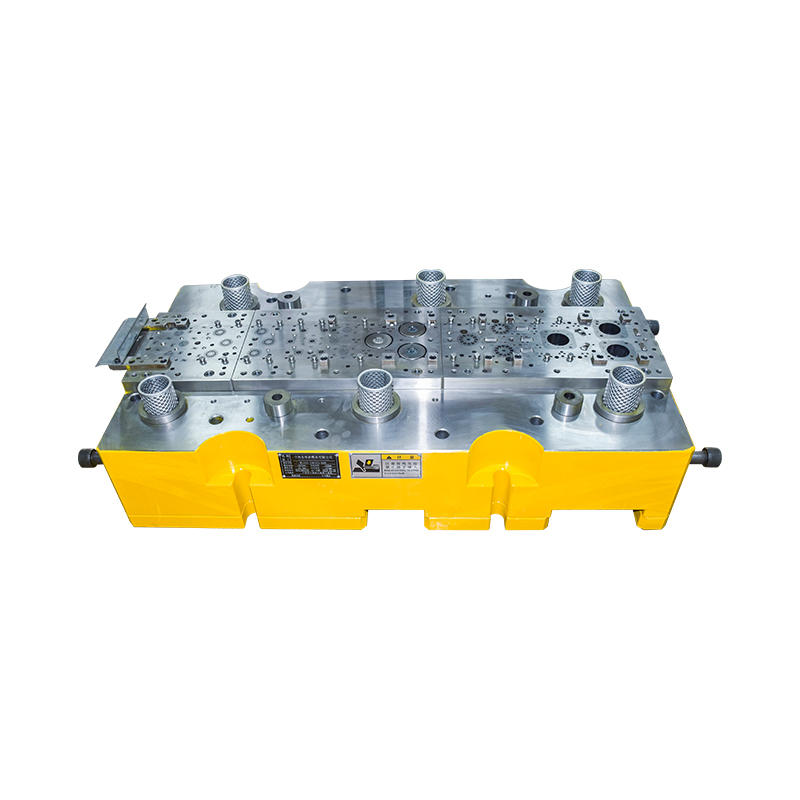

The mold structure of the motor progressive die can be adjusted and designed to some extent according to the complexity of the product, but this adjustment is usually limited. The design of the motor progressive die is optimized to achieve a continuous stamping process with multiple processes and high efficiency. Therefore, its structure usually needs to be accurately calculated and planned based on meeting the shape, size, and production process of specific products. The adjustment and design of molds is not a simple process, especially when facing complex products, which usually requires comprehensive consideration of multiple factors.

As the complexity of the product increases, corresponding changes need to be made in the design of the motor progressive die. For example, products with complex shapes may require more workstations to complete different stamping operations, or finer operations at each workstation, which requires the mold to accommodate more workstations or have higher precision and adaptability. In addition, the complexity of the product may also involve the use of different materials, and mold design needs to consider the different hardness, ductility, and friction characteristics of the materials to ensure that the mold can be smoothly stamped and maintain long-term stability.

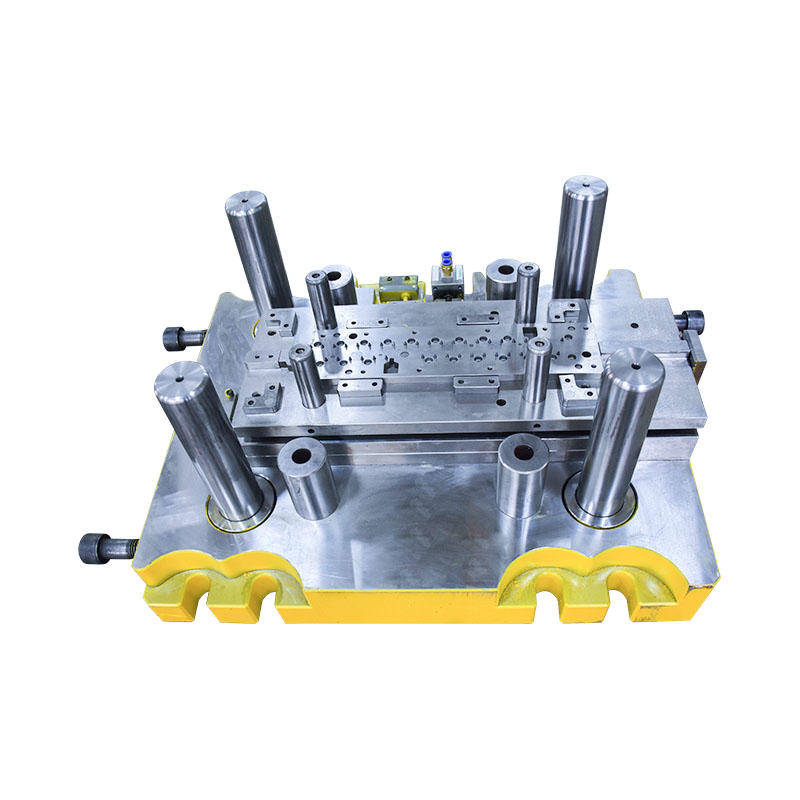

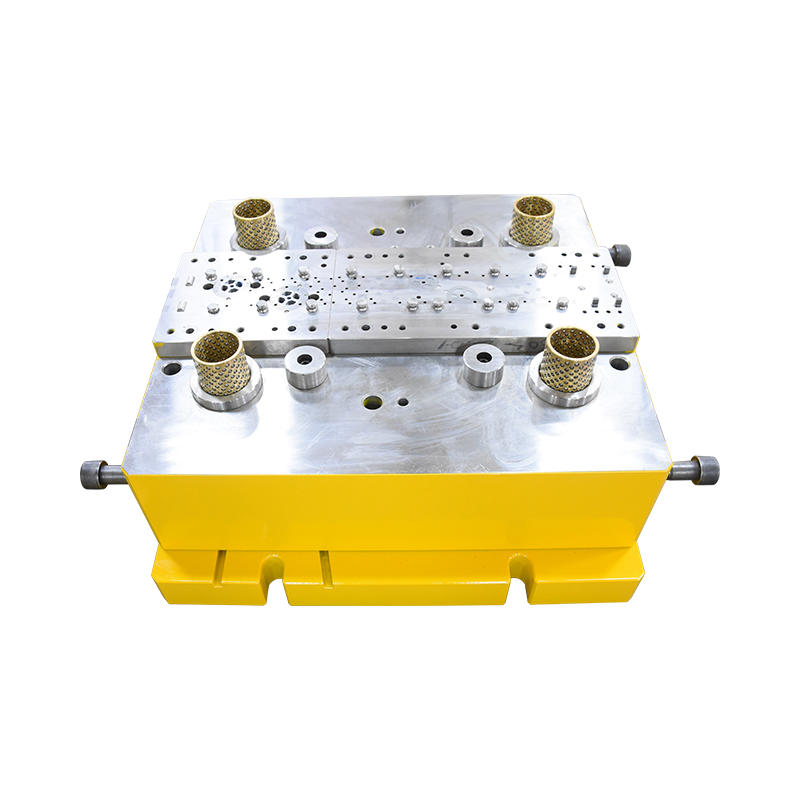

For particularly complex products, motor progressive dies may require more customized designs. For example, certain special products may require more complex manufacturing processes, and the design of molds must be adjusted accordingly based on these processes, including finer workstation layouts, increased adjustment devices, and optimization of mold materials and surface treatments. For some special requirements, the motor progressive die can also adopt modular design, so that different parts of the workstation and mold can be replaced or adjusted according to the specific product requirements. This design approach can provide some flexibility to adapt to more complex production needs.

However, although the mold structure can be adjusted and optimized, the adjustment of mold design still faces some challenges for very complex products. Firstly, the redesign or adjustment of molds often requires a longer time and higher costs, which may affect production efficiency. Secondly, complex product design may lead to a more complex structure of the mold, increasing the difficulty of manufacturing and maintenance. Therefore, although the structure of the motor progressive die can be adjusted and designed to cope with the challenges brought by product complexity, frequent adjustments in design may reduce the economy and production efficiency of the mold in practice.

English

English 中文简体

中文简体 Español

Español русский

русский Deutsch

Deutsch