For parts that require multiple molding, is the motor progressive die also operated in a single station?

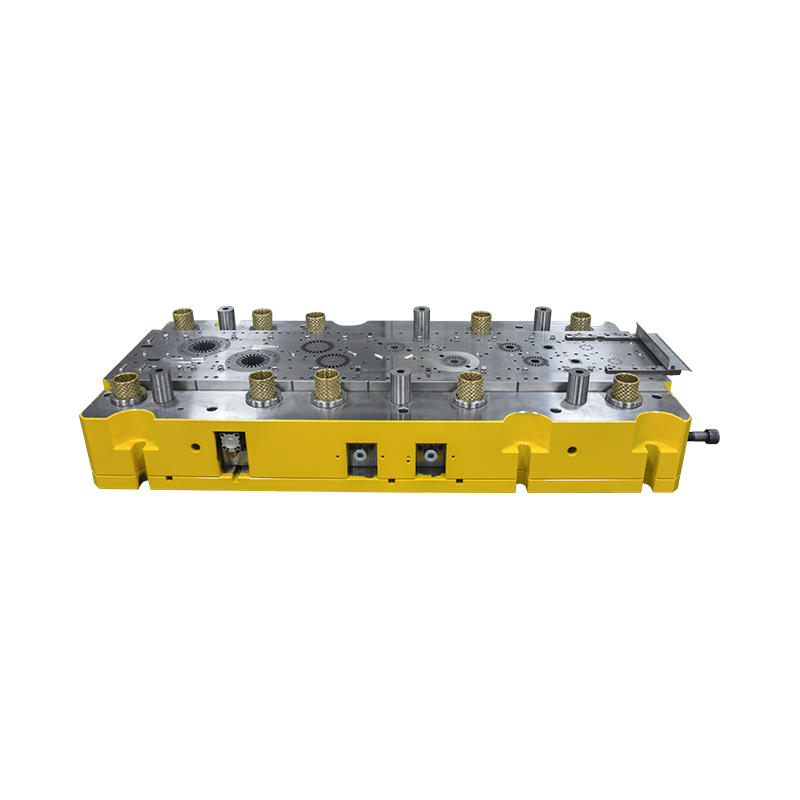

For parts requiring multiple forming, the motor progressive die is usually not operated in a single station, but completes multiple forming steps in the same mold through multiple stations. The following is a detailed point by point introduction:

1. Collaborative operation of multiple workstations

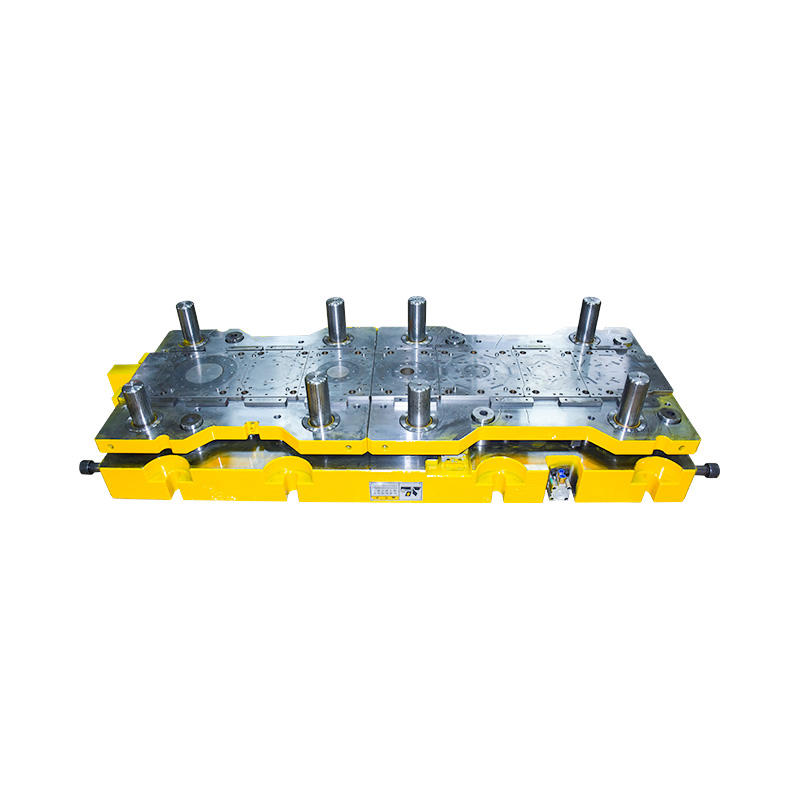

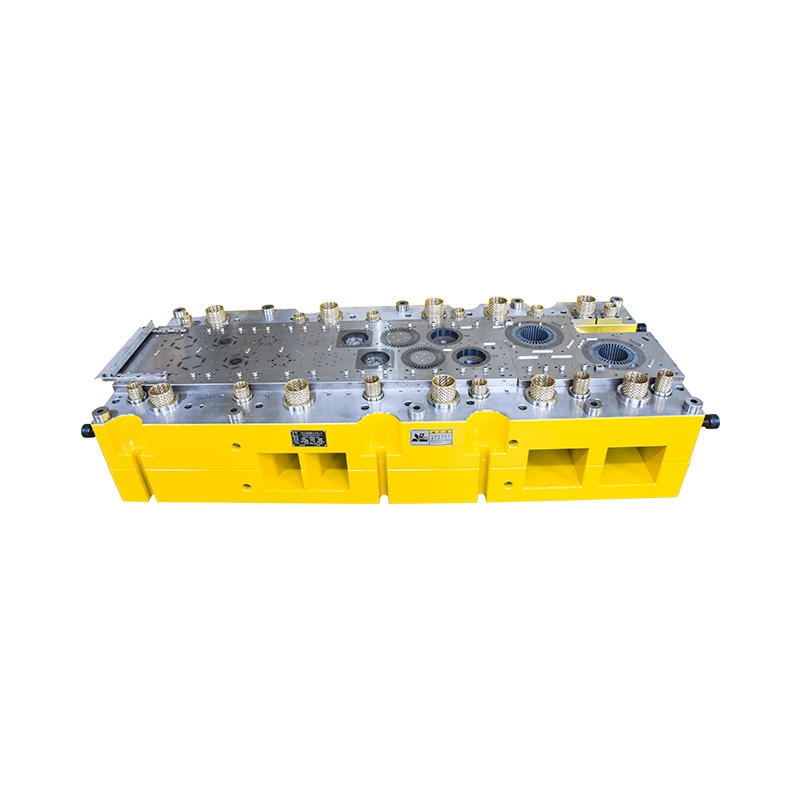

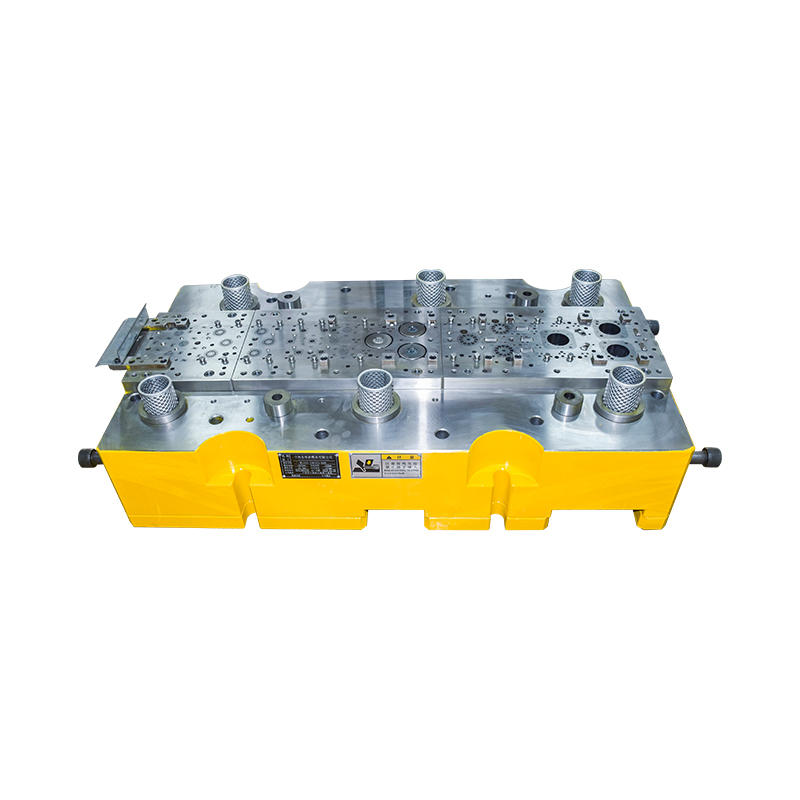

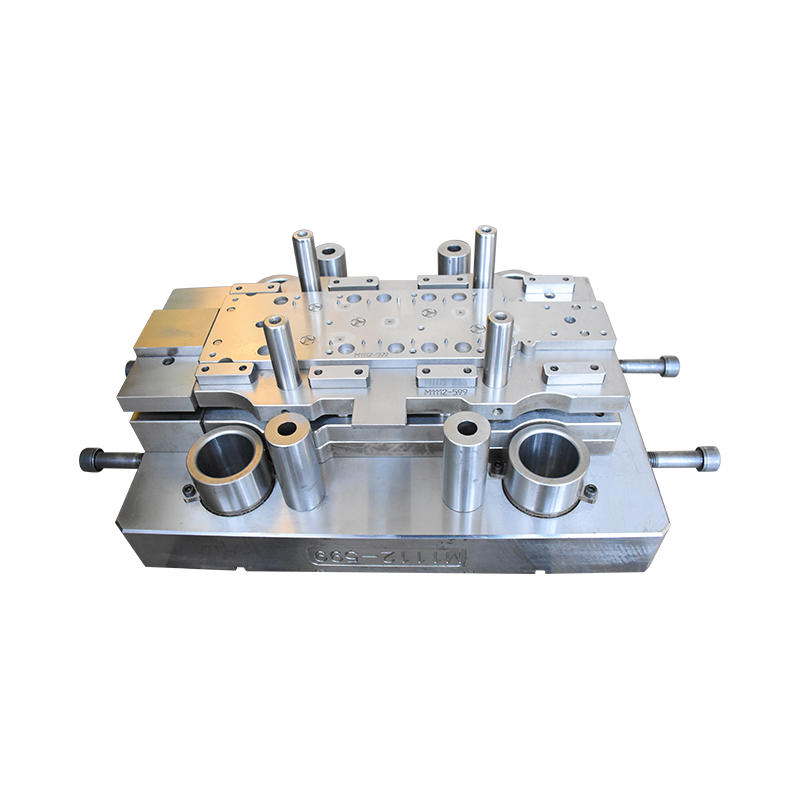

One of the core features of motor-driven progressive dies is the continuous operation of multiple stamping processes through multiple workstations. These stations work together in sequence. Each station is responsible for different forming steps of parts, and multiple processes from preliminary stamping, punching, bending to cutting are all completed in the same mold.

This multi station layout design allows each part to undergo multiple forming operations in one cycle, thereby efficiently completing complex part processing tasks.

2. Workstation allocation and sequence

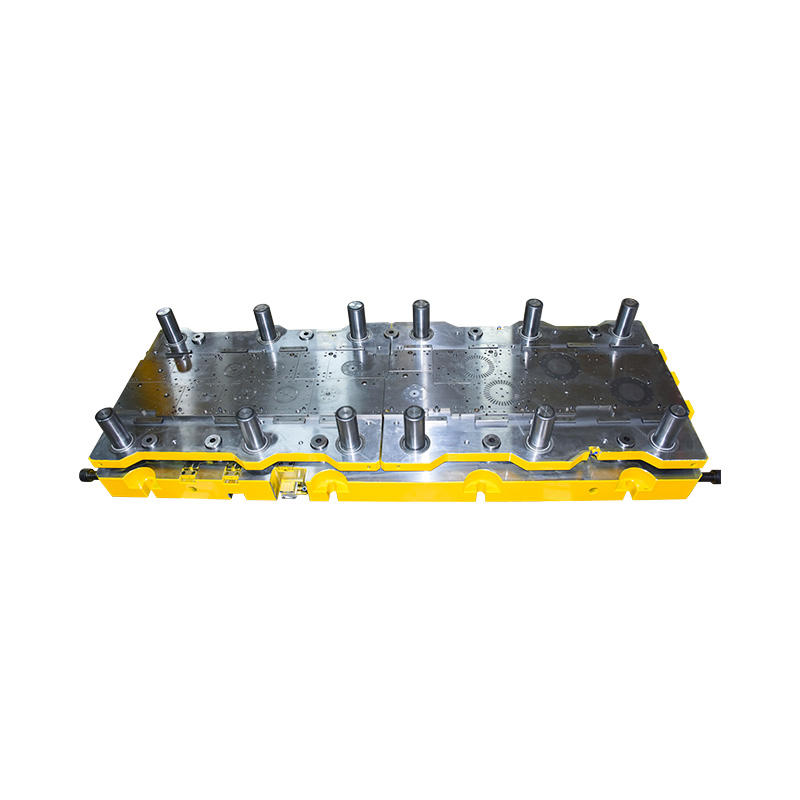

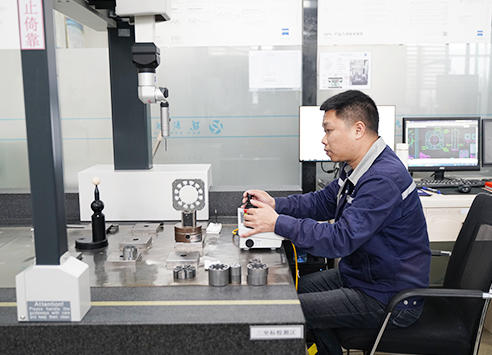

In the motor progressive die, each workstation is set according to the design requirements of the parts. For example, some workstations may be used for rough machining (such as cutting or punching), while others are used for precision machining (such as precision forming or stamping), with each workstation serving a different part of the part.

For parts that require multiple molding processes, this multi station layout ensures that each molding process is progressive, and the parts gradually complete the molding operation.

3. Production efficiency and consistency

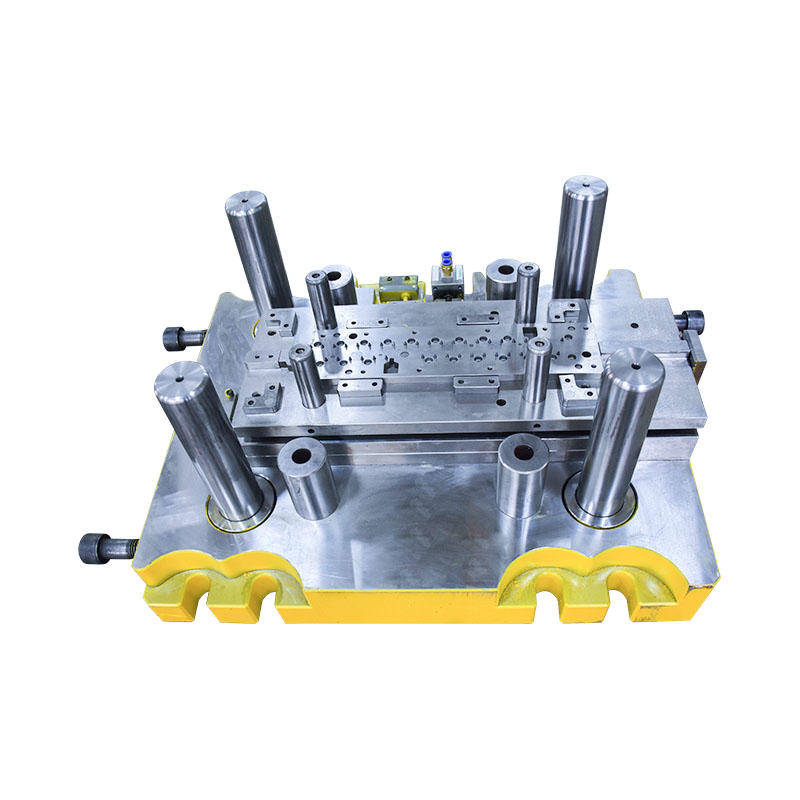

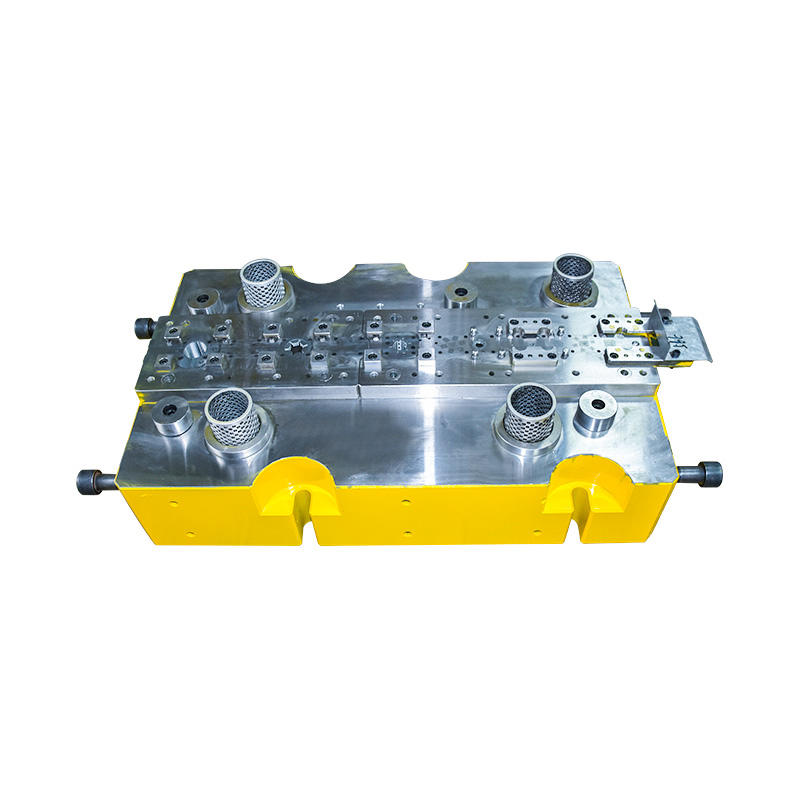

Under the design of continuous operation at multiple workstations, the motor progressive die can achieve efficient production. During each mold closure, the parts will pass through multiple stamping stations to gradually complete the molding process without the need to transfer to other equipment or stations.

This method can maintain the consistency of parts, reduce manual operation and conversion time, thereby improving production efficiency, especially in large-scale production.

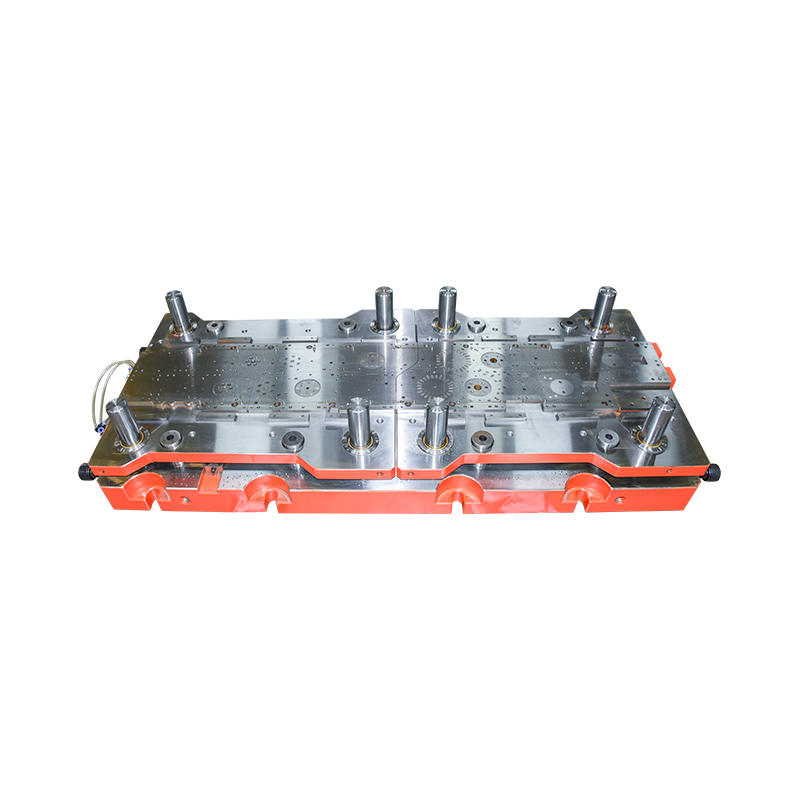

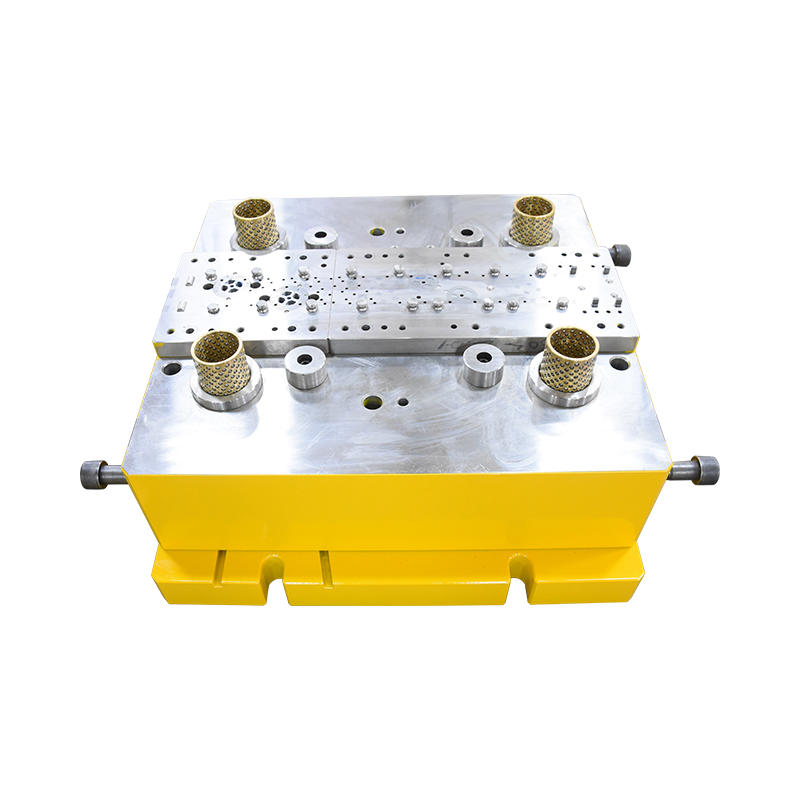

4. Adapt to the processing of complex parts

For some parts with complex shapes and requiring multiple processes, a single workstation molding operation may not be sufficient to meet the requirements. The multi station operation of the motor-driven progressive die can precisely adapt to this complex processing requirement. For example, a part may require different processing at multiple workstations, such as punching, cutting, stretching, etc. These processes are carried out simultaneously at multiple workstations to ensure the accuracy of the part's precision and shape.

English

English 中文简体

中文简体 Español

Español русский

русский Deutsch

Deutsch